The People of Hitachi: Working Toward the Decommissioning of Fukushima Daiichi

Eleven years have passed since the 2011 Great East Japan Earthquake, and Hitachi is now developing technologies to decommission Tokyo Electric Power Company’s (TEPCO) Fukushima Daiichi Nuclear Power Station—the site where the nuclear accident occurred. This is a long-term project, as it is said that it will take 40 years to completely decommission the power station. One of the engineers had this to say about Hitachi’s involvement: "We are undertaking our normal responsibilities as a manufacturer."

The challenge is how safely the highly radioactive fuel debris (the solidified mixture of melted nuclear fuel and other materials that remain inside the reactor) can be removed. In contrast to the Three Mile Island and Chernobyl nuclear accidents, the removal of the fuel debris at Fukushima Daiichi Nuclear Power Station must be performed using methods that have never been tried before.

There is one young engineer who began working the year after the earthquake and is working toward the revitalization of Fukushima.

First-ever mission in human history

Hitachi City in Ibaraki Prefecture is home to many Hitachi Group facilities. Munenori Tayama (34) of Hitachi’s Nuclear Energy Business Unit works at the Rinkai Works near Omika Station. He is a member of the team that is developing the technical methods to remove fuel debris as well as robots that can work in areas that humans cannot enter.

Regarding his team, Munenori explained: "Our team is comprised of a total of about 20 people, and I am responsible for five working members. A variety of technologies need to be combined to remove the debris, so we consult with internal and external professionals to find effective technologies, create prototypes, and conduct experiments."

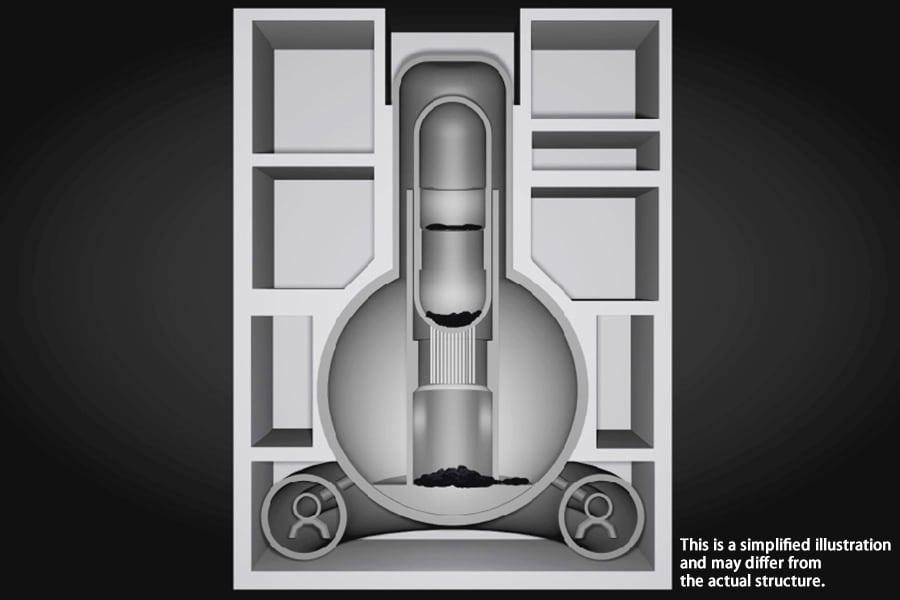

At Fukushima Daiichi Nuclear Power Station, there is estimated to be 800 tons of fuel debris that formed during the accident caused by the 2011 Great East Japan Earthquake. However, as humans cannot enter the primary containment vessel, its interior has not been completely surveyed yet, and no one knows the state inside.

Munenori commented: "The most-difficult mission is how to access the primary containment vessel and safely remove the fuel debris from there."

In previous nuclear accidents, measures were taken by enclosing the nuclear reactor with concrete or removing debris by filling the primary containment vessel with water.

However, in the case of Fukushima Daiichi Nuclear Power Station, the reactor pressure vessel and primary containment vessel is severely damaged, making the same measures impossible. Therefore, the reactor must be decommissioned by "removing the debris from the building as is and storing the debris somewhere else," which is a method that has never been tried before in human history.

Childhood longing for robots

Munenori was born in Hitachinaka City, Ibaraki Prefecture, which is next to the village of Tokai, where Tokai Power Station, Japan's first commercial nuclear power plant, is located. Hence, he has been familiar with nuclear energy since he was a child.

He first became acquainted with robots in elementary school. The first robot he ever saw was a robot made by a student from National Institute of Technology, Ibaraki College at an event held in the city.

"I saw a demonstration of a robot walking up some stairs at an industrial fair that I visited with my parents. According to them, I just kept staring at the robot. Because I kept looking at it for so long, I was given permission to operate it by myself."

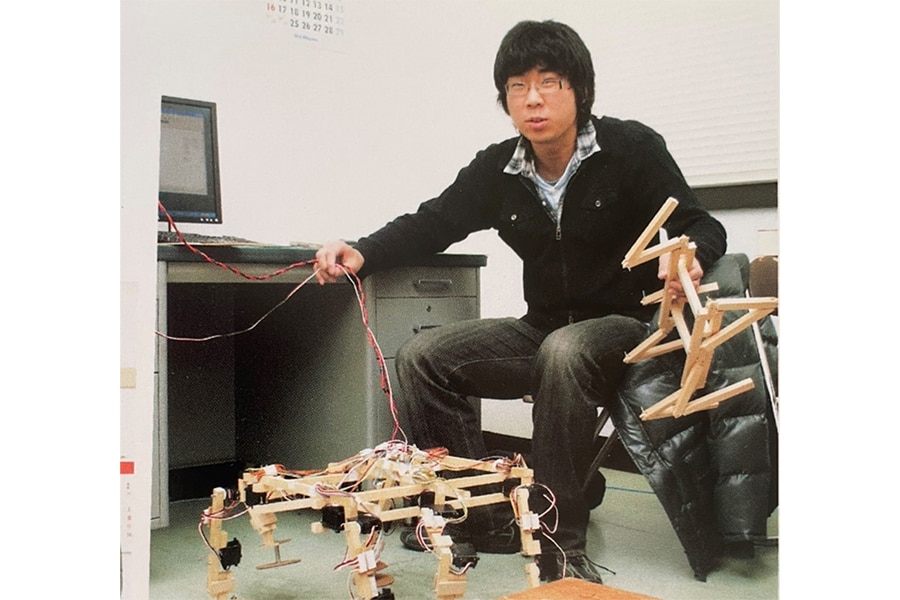

After he graduated from middle school, Munenori went on to Ibaraki College, which sparked his interest in robots. For his graduation research work at the associate degree program, Munenori developed a six-legged robot that could walk steadily in disaster areas. He then went straight into a bachelor's degree program and devoted himself to researching walking robots. After that, he entered the graduate school at the University of Tsukuba, where he studied assistive suits used in medical and other industries.

Munenori started looking for a job in 2010 while he was in graduate school. At the time, the winds of a nuclear renaissance were blowing overseas, with the idea that more nuclear power plants should be built to move away from fossil fuels. He also felt such trend and had a vague idea that he would like to take advantage of his knowledge of robotics and find a job at a company involved in nuclear energy.

A sense of mission after the earthquake

And then, on March 11, 2011…

When a huge earthquake with a magnitude of 9.0 occurred in the Pacific Ocean in the Tohoku region, Munenori was in his lab at University of Tsukuba. Unbelievable images were shown one after the other on TV of a massive tsunami hitting Fukushima.

When the news reported that a building at Fukushima Daiichi Nuclear Power Station had exploded, he was worried "wondering about what was happening inside the plant," and at the same time, he felt a certain feeling welling up inside himself.

"I want to contribute to the safety of nuclear power, and I have to do something to support Fukushima."

He chose Hitachi as the place he wanted to work at.

He was immediately assigned to a department that is responsible for the decommissioning of Fukushima Daiichi Nuclear Power Station. His boss told him: "I want you to make use of your knowledge in researching robots."

Looking back at that time, Munenori said: "Once I joined Hitachi, I was determined to carry out this task." And he inspired himself by saying: "Someone has to do it."

Developing retrieval methods to remove debris

That is how Munenori became involved in the decommissioning project. Since then, he has been developing retrieval methods to remove the fuel debris and is mainly looking into two methods in particular.

One is the "Top Access Method" in which the debris is retrieved via an extraction facility on top of the reactor building. A crane is installed on the top of the building, which then grabs the debris from the top to remove it.

The other is the "Side Access Method" in which an extraction facility is built on the side of the reactor building and a robot is inserted from the side access door to reach the debris. While building a facility on the side is easier than the top access method, the drawback is that only a small robot can be inserted, so the amount of debris that can be removed each time is small.

Regardless of the method selected, the work is predicted to take an enormous amount of time. Therefore, Munenori's team has also developed the "integrated-removal method," which expands upon the top access method. They believe that this technique will make it possible to remove large pieces of fuel debris without breaking it down into parts inside the reactor and thereby improving both safety and efficiency.

"This technique may allow us to decrease the amount of work in highly radioactive areas and to also shorten the work schedule."

Robots: Essential for debris retrieval

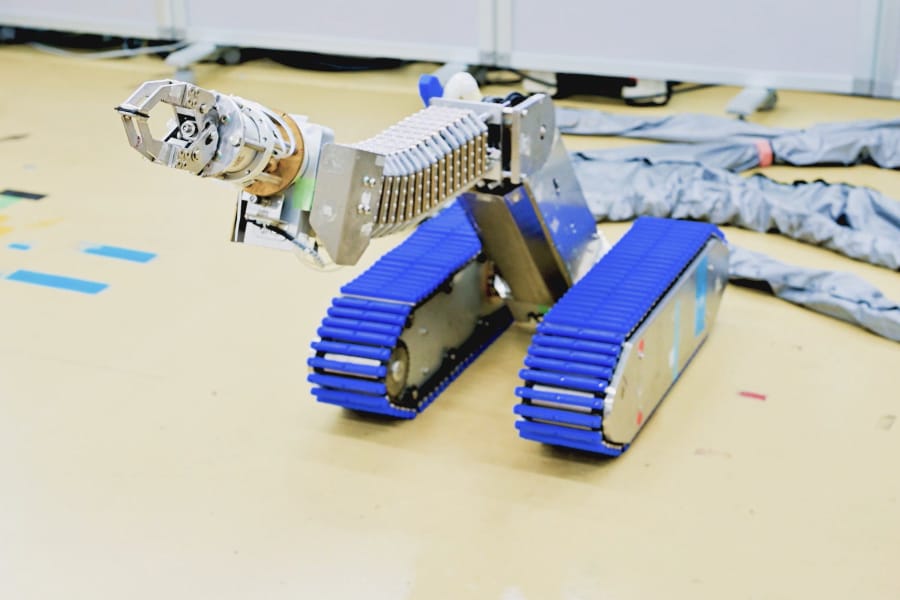

In addition to the development of retrieval method, robot development is also essential for the removal of the debris. As rubble from the destroyed building is scattered around the inside of the reactor, the area where the debris is located cannot be accessed easily. The amount of radiation is extremely high, so it is impossible for humans to clear the obstacles by hand.

To overcome this problem, Munenori’s team jointly developed a "muscle robot." The robot arm is flexible and is controlled by water pressure, enabling the robot to enter tight spaces where there are obstacles and perform delicate tasks. Furthermore, as the robot can function without any electric circuits, it is not susceptible to the effects of radiation.

Through the development of the "muscle robot," his experience in robotics research from his student days has finally come into use. Expectations are rising for this robot to make significant progress in the decommissioning work.

"We constantly gather wisdom both internally and externally, and we repeatedly build prototypes to check if the idea works. I’m motivated to see our ideas taking shape, and I also enjoy working with colleagues that have the same awareness of the mission that we are facing."

"We can change Fukushima’s future."

It has been exactly 10 years since he joined the company. Munenori has been involved in the decommissioning project his whole career up to now, but it is projected that it will take 30 more years to complete the decommissioning of the power station.

"I don’t know whether the decommissioning will be completed by the time I reach my retirement. The full-scale fuel debris retrieval process will not begin for a while, but in the meantime, I want to keep developing my skills so that I can be an engineer who can play a coordinating role when the time comes."

What motivates Munenori to continue with such seemingly endless work? The answer lies in his passion for Fukushima.

"This is a job for which the future is hard to predict, but our goal is very clear: to decommission the power station. We just have to keep heading toward that goal. I want to, and I believe that we can, change Fukushima’s future with the technologies that we have."

Munenori will continue to move forward in safely decommissioning Fukushima Daiichi Nuclear Power Station.