The manufacturing industry is facing the diversification of market needs and the need for high-speed management. To deal with this, a model needs to be established that enables high-efficiency and high-quality production, even for the high-mix low-volume production accompanying these changes. The key to this is using digital technologies to streamline and upgrade work that requires human judgment. At Omika Works, Hitachi has merged JUKI's production facilities with Hitachi's operations know-how, endeavoring to bring about greater advances to printed circuit board production lines, including such initiatives as the full automation of parts storage and retrieval. In partnership with JUKI, Hitachi will engage in collaborative creation with a view toward providing advances for these initiatives in the form of new solutions to users leaning toward making use of smart factories.

*1 MONOZUKURI: Japanese term for manufacturing

Japan's manufacturing industry is facing a variety of issues, including dealing with mass customization aimed at diversifying market needs, shortages of skilled technical workers caused by a falling labor force population, and others.

Hitachi is no exception. Omika Works, located in Hitachi City in Ibaraki Prefecture, handles the development and manufacture of control systems for electrical power, railways, and other social infrastructure, and most of these systems have individualized specifications. For this reason, the printed circuit boards mounted in these systems are manufactured in-house, with over 30,000 produced a month under 24-hour production.

Omika Works handles a tremendous number of types of materials and components in its high-mix low-volume production.

Kazuyuki Tashiro, senior engineer, IoT Systems Engineering Department, Omika Works, Hitachi Insight Group Control System Platform Division, Hitachi, Ltd.

The manufacture of printed circuit boards requires up to 10,000 types of materials and electronic components. Due to the complexity of the pre-production process, which includes parts storage and retrieval, inventory, and order placement, there is frequent need to perform tasks such as changing manufacturing equipment setups and exchanging parts. It is problematic to grasp at a glance the operational status of a large number of machines lined up in a row, thus human workers must have experience and knowledge in order to make accurate judgments about next-process setups. Additionally, in obtaining full production capacity over 24 hours, Omika Works' desire was to minimize line downtime even when there are sudden investigations for unexpected equipment failure.

To address this, Hitachi took the occasion of the upgrading of production line equipment as an opportunity to incorporate IoT to optimize its production lines. JUKI, a global supplier of mounters (devices for mounting electronic components on printed circuit boards) and automated warehouses for printed circuit board production lines, was recruited as a partner for this project.

Looking back, Kazuyuki Tashiro, senior engineer of the IoT Systems Engineering Department at Omika Works, says that: "JUKI has a number of strengths, such as automated warehousing, image recognition technology needed in fault analysis, and so on. However, as we approached the limits to speed increases for individual devices, it was recognized that, in providing Hitachi’s solutions, the key to differentiation with competitors was to improve the efficiency and sophistication of the work along the line that is still performed manually. On the other hand, we have know-how in collecting worksite data using IoT and then using this to improve production efficiency and quality through OT (operational technology). We agreed that combining these strengths would not only raise efficiency and sophistication, but also stimulate the creation of new solutions that use digital technologies that encompass areas that were previously the responsibility of human workers."

In September 2018, Omika Works introduced new models of JUKI mounters. In addition, the pre-production process of the production line received an automated warehouse for electronic components and automated transport machines (automated guided vehicles, or AGVs) made by JUKI. This signaled the start of initiatives by JUKI and Hitachi to streamline and upgrade overall operations.

Mr. Tadashi Atsumi, general manager of system development department of JUKI Corporation, spoke about the background to the startup of this project, as follows:

"The Omika Works production line has various production equipment whose operation rates and quality standards are maintained at a high level, thus keeping their performance at the maximum. With the Omika Works as our stage, we felt that, if we could develop a digital technologies-based solution that leveraged both of our strengths, this would lead to a major step forward for our global business."

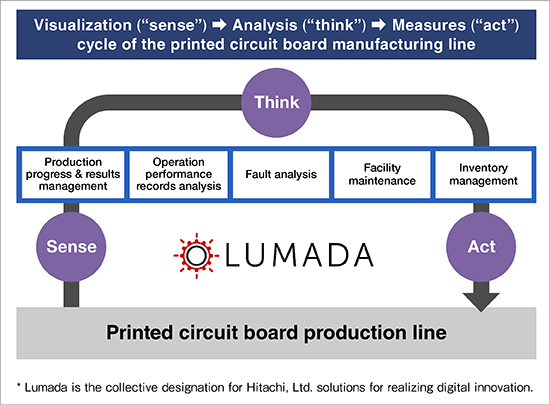

Figure 1: General schematic of the “Printed Circuit Board Production Optimization Solution”

Top photograph: Receiving components from an AGV that has arrived line-side

Bottom photograph: Large monitor for assisting in judgments by the operator; allows tracking in real time of production progress and facility operation status

Upgrading across the entire production process entailed two general points. One was the automatic supply of needed parts before they were depleted, accomplished by using an AVG to connect the automated warehouse, located before pre-production, and the mounter. The other was the collection of production performance records and operational information from each device in real time for the purpose of assisting on-site decision-making.

Hitachi and JUKI then initiated a double-faceted approach that combines digital technologies (i.e., the processing in real time of diverse data output by production equipment and feeding this back to control) with operation know-how—that is, what it is that can be improved by connecting certain types of data and then analyzing them in certain ways.

In particular, this project saw the use of know-how and experience in using IoT to go through the “STA cycle”. This means to visualize (“sense”) the worksite situation, analyze (“think”) it, and then carry out measures and improvements (“act”) as feedback to the worksite. See Figure 1.

Kazuyuki Tashiro goes on to say that: "Over the course of our many discussions with JUKI, we built a system for visualizing data collected in real time from each piece of equipment and a system for quickly feeding back the results of operation performance records analysis to production planning. We made use of our accumulated know-how, examples of which are methods of information display that allow an intuitive understanding of the worksite, methods of analyzing collected data, and applying this to process improvements, etc."

Beginning with component storage and retrieval operations, the receipt by an AGV of a "component low" warning from a production device initiates the on-demand delivery of the target component from the automated factory to line side. This process is totally unmanned, and even more labor-hour savings are achieved due to the centralized management of inventory by the automated warehouse. (Top photograph)

On the line itself, a large monitor is set up that visualizes the progress of production. Always within the field of view, this screen can be looked at by managers and workers alike, allowing them to precisely share worksite status and, based on this, to flexibly judge the proper allocation of production resources, changes to production plans, and other such tasks. The operational status of the numerous mounters is also displayed, making the worksite a place of speedy action. (Bottom photograph)

Mr. Tashiro adds: "As a result of these initiatives, we achieved higher facility operation rates and made possible the continuous 24-hour operation of the line with just a small number of people. Another major benefit was how it became possible for managers and workers to 'converse' in terms of the values they are viewing. This gives us the chance to make concrete considerations on improvement methods when problems occur, such as if there is a problem in production planning or if worker motion should be changed."

Furthermore, Production Progress & Production Performance Records Management, one of the products of the Printed Circuit Board Production Optimization Solution developed over a half-year effort, was introduced by JUKI Industrial Equipment Technology Corporation (JTEC), a company in the JUKI group, where the product was subjected to verification testing to determine benefits. Mr. Kohei Suga, manager of production engineering sec. of JTEC, explains the benefits of implementation, as follows.

"Being able to look at information on a large monitor has made it possible for us to judge in a timely manner what we should do next and what kind of setup we should do in advance, for example. Managers and workers also gained the ability to share awareness, with productivity improving about 30% in one month after introduction."

Printed circuit boards are used in various types of electronic devices. Developments in diverse smart devices and IoT sensors will spur an acceleration in their demand and in the trend toward their high-mix low-volume production. In this respect, Hitachi and JUKI have plans to link the “Printed Circuit Board Production Optimization Solution” with JUKI products for deployment to domestic and international users aspiring to make use of smart factories. Future plans also include using AI to analyze information acquired from all production devices, in order to assist in optimal production planning, as well as providing an O&M service that will maximize the operation rates of customer facilities.

As Mr. Tashiro states: "In opposition to the rise in the overseas production of products that can easily be mass produced, Japan still retains, to a large degree, high-mix low-volume production as well as a MONOZUKURI system that still retains elements of human judgment. But, as this entails the issue of shortages in successors and labor, how can we use the power of IT and OT to make the advances and achieve the automation needed to compensate? Our mission is to keep on reporting from the worksite on the technology and know-how required for solutions to this issue."

Changing the production paradigm to create innovation—the source of this always lies in the buildup of genuine conflict and improvements amid manufacturing operations. Hitachi has three faces: one as a user that utilizes a MONOZUKURI reform system at corporate sites, one as a vendor that develops and provides products, and one as a joint service provider that, as in this case, jointly provides solutions created collaboratively. Hitachi will continue to provide robust assistance for the digital revolution of domestic and international manufacturing industries through collaborative creation with customers.

Main factory of JUKI Industrial Equipment Corporation, located in Yokote City in Akita Prefecture

Release Date: March 2019

Solutions By: Control System Platform Division, Hitachi, Ltd.