An increasingly common challenge for manufacturers is how best to cater to constantly changing demand amid rapidly diversifying customer needs and intensifying global competition. In recent years, more manufacturers have had to attain mass customization that delivers productivity equivalent to that of mass production, even for ultra-high-mix, low-volume manufacturing. Some Japanese companies have therefore started leveraging their strengths, integrating such advanced technologies as the Internet of Things (IoT), big data and artificial intelligence (AI) with skilled manufacturing techniques. A good proponent of that approach is Okuma Corporation, a leading machine tool manufacturer. Ultra-high-mix, low-volume manufacturing and the assembly of massive numbers of parts to match diverse customer needs is pivotal to manufacturing machine tools. Here, look at how Okuma is successfully tacking the challenges of change.

An interior view of the new factory Okuma launched for the world's best manufacturing services.

Okuma Corporation is a comprehensive machine tool manufacturer established about 120 years ago. Based in Aichi Prefecture, Japan, this leading global player continues to build momentum through a diverse range of machine tools that includes Computerized Numerically Controlled (CNC) lathes and multitasking machines, machining centers and grinders.

In 2013, Okuma started operation of Dream Site1 (DS1) to realize “Made in Japan to Win Around the World.” At the time, a soaring yen was punishing manufacturing in Japan, prompting many players to shift operations offshore to survive. But Okuma knew that its competitiveness lay in the manufacturing prowess it had cultivated in Japan throughout its history, and bucked industry trends by investing heavily in its domestic production infrastructure.

Mr. Atsushi Ieki, a Senior Executive Director at Okuma, recalls that, "We knew that Japanese manufacturing industry could regain ground by eliminating waste." This bold decision came to splendid fruition, notably abound through the multitasking machines, medium-to large-sized lathes and vertical lathes from DS1 that fully automate production facilities and visualize operational conditions, dramatically improving factory productivity and capacity utilization.

In 2017, the company built the state-of-the-art DS2, an advance on the DS1 in the drive toward the mass customization of machine tools. The DS2 was designed to make around 4,000 parts in high-mix, low-volume machining, compared with around 1,000 at DS1, and create diverse small to medium-sized lathes and grinders. DS2 symbolized Okuma's mission to construct a very highly-efficient manufacturing model that can cater to short manufacturing lead times owing to changes in orders, schedules, and specifications, manufacturing just what is needed, only when sought, and only in the quantities required.

Okuma considered three key factors in its quest to build an advanced factory that could realize mass customization. The first was to improve productivity through automation, unmanned operation, intelligence, and integrated processes. The second was accelerate factory control cycles*. The third was to visualize production for total optimization.

At DS2, Okuma has progress with automation by using advanced robots and flexible manufacturing systems (FMS), focusing on its strengths in intelligent systems and smart machines that integrate processes. By leveraging robots, Okuma has been able to overcome the challenges of conventional manufacturing, improving productivity in processing heavy parts in a high-mix, low-volume manufacturing.

The company faced vast new challenges in accelerating factory control cycles and visualizing production for total optimization, and explored external collaboration to ensure success in entirely new areas.

Mr. Ieki notes that, "We looked into working with various vendors. The optimization frameworks for entire factories are very broad, however, and few companies could handle the total flow that we envisioned. But Hitachi knows the insides and outs of manufacturing, and has technologies for controlling production lines and entire plants. We realized that we could accelerate factory control cycles and visualize production for total optimization by combining Hitachi's expertise with our capabilities."

Initiatives at Hitachi's Omika Works influenced Okuma's decision. That facility develops and produces control systems for railways, power, water treatment, and other social infrastructure, and engages in high-mix, low-volume manufacturing like Okuma.

To ensure efficient production for diverse product families, the Omika Works built an IoT environment within the site that uses Radio Frequency Identification (RFID) IC tags. Real-time collection and usage of man, machine and materials information enabled the facility to halve production lead times for main products. A highly-efficient production setup combines operational (control and operations) technology and information (data analysis and application) technology. Mr. Ieki recalls that this Hitachi approach was very extremely helpful for Okuma.

Thus, Okuma and Hitachi embarked on the path to collaborative creation. For their project, core representatives from Okuma and Hitachi met repeatedly and discussed a new manufacturing framework. They reviewed everything from reconfirming management-level objectives to dramatically improving productivity at the machining level on site, reducing lead times, and visualizing production processes.

In combining Hitachi's expertise at its Omika Works and Okuma's know-how from DS1, the two partners created a process control system that accelerates factory control cycles and a progress and operational status monitoring system to underpin the evolution of production visualization.

Hitachi's Omika Works which influenced Okuma's new factory had built an IoT environment within the site that uses Radio Frequency Identification (RFID) IC tags to halve production lead times for main products.

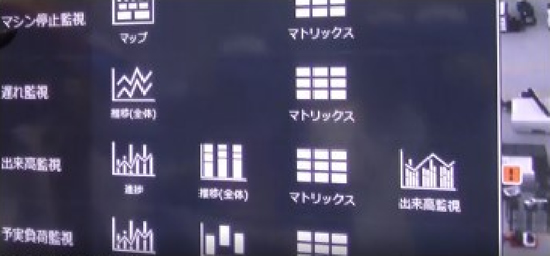

A list of the production facilities to be monitored

The detailed information is available by drilling down.

Although it is early days yet, DS2 has already proven effective. For example, it has accelerated factory control cycles by issuing job instructions on an hourly basis instead of weekly under conventional setups.

By using the RFID tags that Hitachi's Omika Works deployed, Okuma has been able to centralize the management of parts tracking on site. Although it used to be able to track parts up to the process level, Okuma now knows where all parts are on an hourly basis, including those moving between processes.

Okuma has been able to integrate production visualization by using IoT to gather and link data on production progress and facilities operational statuses using IoT. Hitachi developed a system to conduct advanced analysis of collected data. The system enables Okuma to detect process bottlenecks (including delays in prior processes and on-site failures) and deploy total optimization measures.

Hitachi plans to use artificial intelligence to refine this system to automatically generate high-precision production schedules as shop floor situations change.

For these process control systems, it applied Production Planning Optimization Solution, by the IoT platform “Lumada”.

Mr. Ieki notes that, "Previously, machining times for some parts exceeded requirements. But after we deployed the solution for Production Planning Optimization, we were better to cater to sudden changes in plan and comply with standard machining times. If we can shorten production lead times, it becomes more efficient for us to manufacture in Japan than anywhere else in the world. Accelerating factory control cycles and evolving production visualization will improve throughput for entire factories by making PDCA cycles faster. So, this setup is vital for us to enhance our global cost competitiveness."

Okuma is pursuing a full automation by using industrial robots.

Okuma plans to apply its expertise from DS2 at other factories to enhance the productivity of the entire company while addressing diverse customer needs in the global market. Down the track, it will create new services that contribute to smarter manufacturing for its customers.

Mr. Ieki says that, "Okuma aims to become the world's best manufacturing services company. Today, the value of any business has shifted away from products to the knowledge it creates. So, the knowledge from manufacturing is the expertise accumulated at production sites. The ability to provide that value to customers should become a key focus of collaborative creation between Okuma and Hitachi."

Okuma has achieved great success in deploying IoT for mass customization in machine tool manufacturing. In so doing, the company has demonstrated the limitless potential of next-generation factories. Collecting and analyzing big data inside and outside factories and applying it to procurement, manufacturing, sales, maintenance, and distribution stages will make it possible to attune demand forecasts to customer needs and optimize production around the world. This model for next-generation factories could help enhance productivity worldwide and contribute to bright vistas for Japanese manufacturing.

Okuma plans to apply its expertise from the new factory at other factories for the world's best manufacturing services.

Release Date: October 2017

Solutions By: Hitachi, Ltd. Industry & Distribution Business Unit