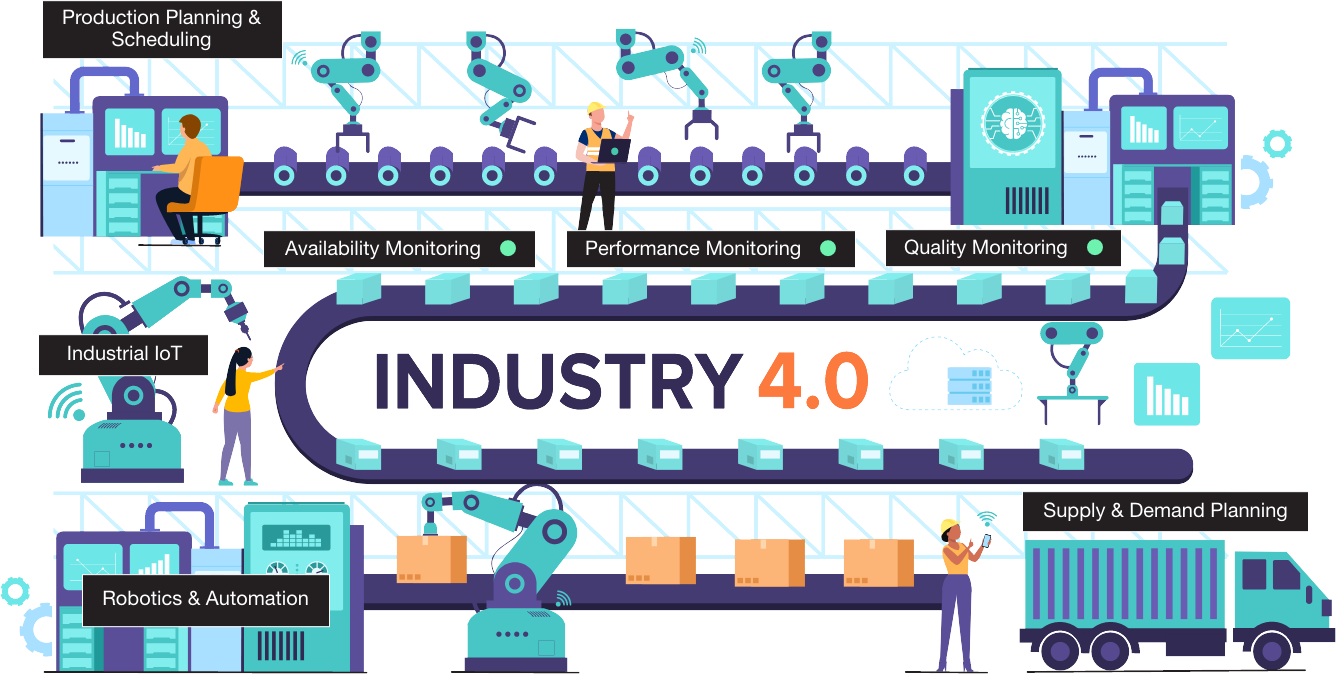

With its transformative potential, Industry 4.0 (IR4.0) is revolutionising the global business landscape. With the common misconception that digital transformations only involve robotics, IR4.0 promises to reshape the manufacturing processes, provide opportunities for businesses to enhance their productivity and competitiveness in the market. Malaysia is not an exception, and Hitachi is continuing to drive its digital transformation at the forefront of IR4.0.

Through the collaborative partnership with Standards and Industrial Research Institute of Malaysia (SIRIM), it established a platform for Hitachi and SIRIM to support Malaysia Government in promoting National Policy for IR4.0 in supporting Small and Medium-sized Enterprises (SMEs) in technologies advancement and convergence where they can be more competitive globally. In 2020, the partners signed a Memorandum of Understanding (MoU) to solidify the collaboration IR4.0 initiative and the launch of Smart Manufacturing Experience Centre (SMEC) in Kuala Lumpur, to deliver their commitment in empowering SMEs nationwide in Connective Industries.

IR4.0 is connecting the manufacturing landscape through the convergence of digital technologies, connectivity, and automation, with the goal of creating a more connective industries. It encompasses cyber-physical systems, the Internet of Things (IoT), big data analytics, artificial intelligence (AI), robotic process automation, and more. By integrating these technologies, manufacturers are aligning with IR4.0 by development of smart factories, which are highly automated and connected. This is resulting in increased productivity, efficiency, and flexibility in manufacturing.

With an extensive portfolio of sustainable innovation solutions, Hitachi offers cutting-edge technologies tailored to innovation needs. From IoT platforms to AI-driven analytics and smart manufacturing solutions, Hitachi empowers businesses to leverage IR4.0 and unlock new possibilities for growth.

Research in 2022 showed that only 30% of Malaysian manufacturers were aware of IR4.0. However, the

nation’s proactive approach towards embracing IR4.0 through initiatives like Industry4WRD is poised to

yield remarkable benefits.

Industry4WRD aims to increase manufacturing productivity by 30% and boost the sector’s contribution to the national economy from MYR 254 billion to MYR 392 billion by 2025.

It also focuses on enhancing innovation and developing a skilled workforce, aiming to raise the proportion of high-skilled workers from 18% to 35%.

The collaboration between Hitachi and SIRIM is instrumental in promoting IR4.0 adoption amongst Malaysian SMEs. SIRIM, a national champion arm in Research & Development (R&D) and technological development, shares Hitachi’s vision of empowering local businesses. In the beginning, SIRIM didn’t have any experience to setup a proper structure to promote IR4.0, so Hitachi brought in Lumada experience and Hitachi’s methodology to help SIRIM materialise their IR4.0 mission.

Moreover, Hitachi is also facilitating the transfer of knowledge and IoT upskilling of SIRIM engineers to be in sync in terms of expertise to further promote IR4.0. This collective effort aims to bridge the digital divide and provide SMEs with a standard platform with the right tools and IoT knowledge required to embrace digital transformation for their industries.

On June 15, 2023, Hitachi and SIRIM marked a significant milestone with the launch of the Smart Manufacturing Experience Centre (SMEC) in Bukit Jalil, Kuala Lumpur. The SMEC is a dedicated hub where industry professionals and SMEs can visualise, learn and experience IR4.0 technologies firsthand.

Equipped with state-of-the-art facilities, cutting-edge tools, intelligent systems, and immersive demonstrations, SMEC enables the Hitachi Group of Companies to showcase a wide range of digital solutions that will enable manufacturers to optimise their operations and unlock new efficiency levels.

Despite the obvious benefits, there are challenges that SMEs may face during their journey to digital transformation:

Through SMEC, SMEs can gain the knowledge, resources, and skills required to navigate these barriers and

achieve sustainable growth successfully.

This long-term partnership between Hitachi and SIRIM, together with the establishment of SMEC holds immense benefits for Malaysian SMEs:

By embracing IR4.0 technologies, SMEs learn the benefit of automation and data insight, they will be able to streamline their processes into an integrated control system and improve production efficiency, and product quality, which gives them a competitive advantage in the future.

Through this collaboration, SMEs gain more access to Hitachi’s vast expertise, methodologies, and technologies to provide a platform where they can receive guidance and support in implementing IR4.0 solutions.

SMEC will play a role as a satellite hub for SMEs to network and collaborate, fostering a culture of innovation and collaboration creation effort to grow their adoption of IR4.0 knowledge and technologies.

SMEC offers training programs to upskill their employees for the digital era and ensure long-term success.

The partnership between Hitachi and SIRIM expedites the digital transformation journey for SMEs, enabling them to stay ahead.

The successful launch of SMEC is only the beginning of an exciting journey in transforming the manufacturing industry. Together, Hitachi and SIRIM are committed to achieving significant milestones and driving continuous innovation.

Beyond SMEC, this partnership’s next steps are to provide training programs for Hitachi’s IoT Solutions and Technologies such as Connected Data Analysis & Analytics, Predictive Maintenance, Connected Products, and more.

Hitachi is also exploring the integration of AI technologies and capabilities into the manufacturing processes, leveraging AI-powered algorithms to optimise production planning, quality control, and supply chain management. This can potentially enable manufacturers to make data-driven decisions, improve product quality, and respond more effectively to the ever-changing market demands.