Smart buildings, smart cities… and now smart farming? It’s an interesting idea that technology can be used on a farm to help create more efficient measures, but how? Taking a farm digital sounds backwards, but Hitachi and Binginbar Farms have proven that traditional farming processes can enter the digital century and set a foundation for the Smart Agricultural age, by undergoing a digital transformation.

Like many modern farming businesses, Binginbar Farms had been operating with a growing number of separate technologies for farm monitoring, as well as different data and financial programs, all of which was becoming inefficient and time-consuming to manage.

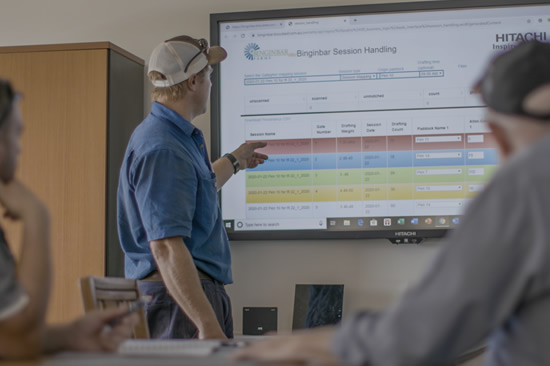

Through effective collaboration with Hitachi, and implementation of their Lumada Solution with BizCubed’s Data Engineering Enablement Platform (DEEP) using Pentaho, Binginbar Farms has begun to integrate all of their information into an efficient, centralised control centre, saving time and taking the guesswork out of important decisions.

The 152 year old farm, located in Gollan in Central NSW is a working example of what effective collaboration with Hitachi can do to improve work efficiency and profitability for Australian farmers, as well as the quality and traceability of Australian lamb.

Video: Creative collaboration between Hitachi and Binginbar Farms - a Ground-Breaking Solution for the Future of Farming

The rapid growth of farm automation has led to an explosion of systems and solutions, each with its own unique processes, making management time consuming and inefficient. Furthermore, even when farm enterprises have business intelligence data available, it may be inaccessible or inaccurate due to a lack of real-time, comparative monitoring. Farmers who don’t have the most relevant insights at their fingertips at the right time are at a disadvantage when it comes to making critical decisions.

Binginbar Farms was a prime example of this situation, with several discrete systems and devices being used for data collection and management. Juggling process flow and operations across these diverse solutions was becoming time-consuming and potentially error-prone.

Binginbar Farms CEO, Nathan Simpson, was aware that the business processes had a missing link between data collection and management, and that something to optimise the farm’s information flow was required.

Nathan first became aware of Hitachi’s involvement in the farming sector when he and his team participated in a farming tour to Japan in 2017. They could see at once the potential for Binginbar Farms and on their return, contacted Hitachi Australia.

Hitachi visited Binginbar Farms a number of times to collaborate with Nathan on the best approach and desired outcome for the farm operation. Part of the solution required sensors to be installed to monitor troughs, pumps and storage tanks, as well as to measure pasture growth, and provide local weather information, and in the office, integration of paddock management and market information tools.

“We can tell how much water the lambs are drinking and if that is less than expected, then we can check for blockages. These include water, weather and soil measurements together with data collected on every single lamb introduced to the property.” Nathan said.

The key success factor was transforming Binginbar Farm’s existing discrete systems into a single digitalised environment by linking the APIs (Application Program Interfaces) of third party software like Xero, John Deere, eID tags and myMLA market data, and the datastreams from on-farm IoT devices such as soil moisture sensors, weather stations and water level sensors.

This was made possible by Hitachi's Lumada Solution, built on BizCubed’s DEEP using Pentaho – a dedicated intelligent system that acts as a central point of integration. Binginbar Farm’s existing data collection resources were able to largely stay in place, minimising the retraining required to adopt the new system. The digital integration and single-point control interface was provided by Hitachi's Lumada Solution.

“The results are pretty clear” Nathan said. “We have a solution that consolidates data sources into a single command center, which helps to speed up decision making in the farm.”

The value-adds of using Hitachi's Lumada Solution are clear: removal of guesswork in livestock management, improvements in animal welfare through accurate monitoring of water and feed intake and more efficient use of data overall.

Underpinning the introduction of sensors, cameras, eID tags and weather stations is the improvement of the Internet of Things (IoT) infrastructure. By using information technology such as drones, sensors, and meteorological tools, “we can ensure that lambs remain at peak health and productivity levels through a process that is efficient in terms of both time and cost.”

“By using eID tags on lambs, coupled with Gallagher tag reader integrated farm management software which provides easy access and reports on individual animal information, we’re provided with real-time data in order to decide which course of action to take.”

“Everywhere we look we see more benefits. If we install frost sensors in a crop paddock, we could use frost event data to map the impact on a crop to help determine if sections are better suited to being made into fodder or being grazed off or to go through to harvest,” Nathan said.

“We’ll be installing cameras on high risk paddocks to monitor stock theft and in one of the feedlot pens we have trouble with wild dogs, so a camera will really help out there.”

Hitachi’s Lumada Solution also opens up other possibilities:

Hitachi’s collaboration with Binginbar Farms is an excellent example of how integrated technological solutions can combine with generations of farming expertise to take the guesswork out of farm management, and to improve efficiency, output and reliability by turning working hard into working smart.

But Hitachi's Lumada Solution, built on BizCubed’s DEEP using Pentaho is much more than a simple fix for over-complex systems. The solution offers possibilities to track genetic productivity by supplier; to improve biosecurity through monitoring animal contact; to better manage feed regime effectiveness; to implement price-driven and biomass-driven strategies for animal management; and to maintain annual yield maps for more efficient land management and yield optimisation.

Hitachi’s Lumada Solution releases traditional farms like Binginbar Farms from the restricted pens of cluttered, unintegrated systems, into the open pastures of digital innovation.

“The guys at Hitachi have been amazing. It really has been a partnership from the beginning.”

“I want to leave the land in a better place for my kids and for future generations. The technology is only going to improve our decision making in ensuring this happens and I’m really looking forward to seeing what this looks like in the years to come.”

- Nathan Simpson, Binginbar Farms

Release Date: March 2020

Solutions By: Hitachi Australia