Design in the "New Normal" Era: Naoto Fukasawa’s Aspirations for Hitachi’s Elevators

Oct. 26, 2021

Shoichiro Kawano

As COVID-19 infections spread, a "new normal" lifestyle is emerging. Under these circumstances, Hitachi, Ltd. and Hitachi Building Systems Co., Ltd. has developed and started sales of the new standard elevator, which delivers safety, security, and comfort for Japanese market.

This is the first standard elevator to be sold in seven years. The new elevator incorporates features for COVID-19 prevention, including automatic ventilation and touchless buttons. In addition to the latest functions, this elevator also boasts a well-received simple and refined design, and orders for it are already pouring in.

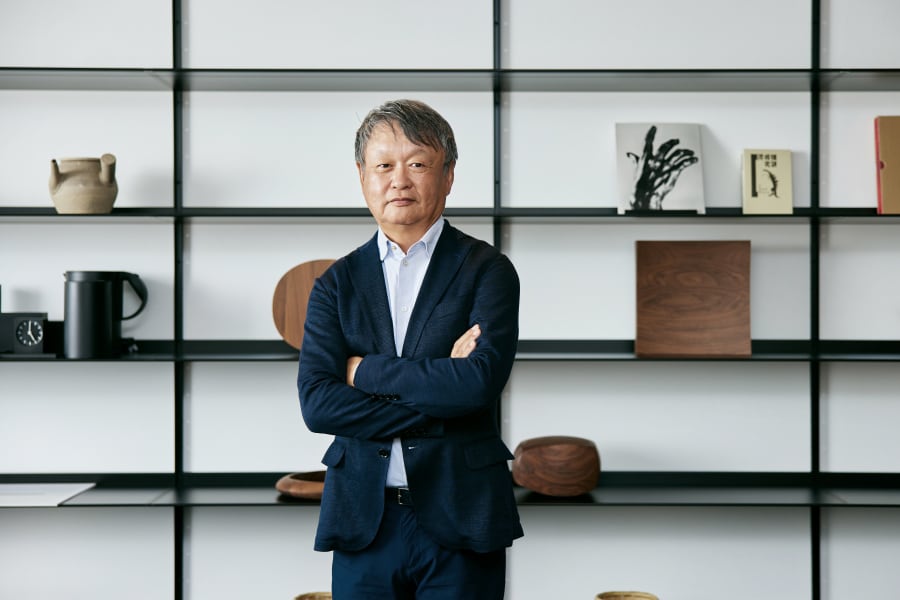

We spoke with Naoto Fukasawa, the product designer who supervised the design, on how the Hitachi’s new standard elevator was developed.

A new type of elevator with measures that fight COVID-19

The new model of elevator began sales in April of this year. Its development started in 2019.

The beginning of 2020, however, saw the worldwide breakout of the COVID-19 pandemic, forcing major revisions to development concepts. The elevator that came out of various discussions has the following features:

- In-car clean operation: If the car is riderless for a set amount of time, the doors automatically open and the ventilation fan starts up to exchange the air. In addition, “nanoe X1” is also produced to maintain car cleanliness.

- Crowding prevention operation: Three levels of crowding are detected based on load capacity. If the level is high, the elevator passes floors. If it is extremely high, an announcement is played that instructs passengers boarding afterward to get off.

- Touchless Button for registration: Passengers can call the elevator and register their destination floors simply by placing their hands near the buttons.

Other features include an 8.4-inch color liquid-crystal display mounted inside the car that displays necessary information during an emergency in four languages and automatic door opening when someone approaches the car as its doors are closing. The new model also supports an original Hitachi service that lets passengers call the elevator using the LINE2 application.3

Looking back at the development process of new model, equipped with these latest functions, Shigeki Iwase of Hitachi Building Systems’ R&D Division says, "There are so many functions and concepts that I'd like to tell you about, that I can't narrow it down to one. But if I did, it would be the design that was completed under Naoto Fukasawa's supervision."

Fukasawa, a world-famous product designer, has been involved in design in a wide range of fields, from electronic precision devices to furniture, interior, and architecture. He and Hitachi engineers teamed up to develop an elevator for the new era.

A design that projects cleanliness

Regarding his approach to design supervision for this project, Fukasawa said that he "focused on beautifying everything down to the finest details." He explains that:

"When I check a prototype, I use the expression 'touching with my eyes.'"

In other words, instead of "looking" with his eyes, he "touches" with them. He explains that when using your eyes to look, you look with great care, making it a conscious activity. But when you "touch" with your eyes, you feel whatever is there unconsciously.

"When you are 'touching with your eyes', you are in a mental state of unconsciousness. If there is some discomfort with the space or sensations in the memories stored in one's own brain, this process will catch it. I want passengers of the Hitachi’s new standard elevator to be able to bask in the refreshing cleanliness projected by the design without any such discomforts."

The process of "touching with one’s eyes" reaches as far as the precision of the areas where steel plates join such as the car corners, the size of the illumination, and the elimination of even the slightest edges on the operation panel.

Fukasawa said that "I put my efforts into creating a space that effectively harmonizes people and the interior of the car, where light from the ceiling flows around in such a way as to give passengers a beautiful look."

The new model has two types of designs: CLEAN and CLASSIC. CLEAN features an interior in which all surfaces, such as the side panels and ceiling frame, have a consistent color finish. CLASSIC combines side panels incorporating wood grain surfacing material with aluminum silver.

Says Fukasawa, "The CLASSIC design emanates warmth, while CLEAN creates an impression of cleanliness. Although many designers like the color of white, to some users it gives the impression of getting dirty easily, so I took great care in adjusting the color finish."

The hard work: Color reproduction and bending

Fukasawa submitted design proposals. Based on these, the development leader, Iwase, along with Hitachi Building Systems' engineers, applied a trial-and-error approach to producing prototypes. Each repetition of this process pushed the development of the new model forward.

Development encountered a variety of challenges. One that required hard work was ensuring that the interior color of the elevator car was consistent.

Inside the car and next to the doors, there is a wall on which the buttons are mounted. With the new model, the upper and lower parts of that wall are steel, while the center, where the buttons are located, is plastic. Fukasawa's design specified that the steel and plastic components should be the same color.

However, as Iwase and his team members proceeded with the project, they were unable to achieve this. They found that even if the color samples were the same color, the colors of the finished steel and plastic components were ever so slightly different.

There were even cases of different colors being generated according to the direction they were coated in. Silver being the most troublesome color, it went through four trials.

Another stressful problem for Iwase was how to bend the plate components of the elevator.

Elevator walls are made by combining steel plates that have been bent. Fukasawa proposed the idea of imparting a soft look by loosening the bending radius of the plates.

Loosening the bending radius in accordance with the proposal, however, would require new molds. To deal with this, Iwase applied his 30 years of development experience to present to Fukasawa his own proposal of using equipment and bending jigs already in the possession of the company instead of making new molds.

Studies concluded that the optimal bending radius could be derived, leading to the adoption of the proposal for the product.

Commenting on this, Iwase said that "I hesitated at first to present an alternative proposal to Fukasawa's design because, after all, he is world famous. But when I communicated our circumstances to him, he thoroughly approved. He then came up with a design that would act as a solution. I felt that he was a solidly grounded man."

Reflecting on his aspirations for the "New Normal"

Fukasawa began his involvement with Hitachi's product development in 2000. By providing his opinion on household electric appliances and by engaging in exchanges in which he provided advice, he built “easygoing relationships” in which people can talk back and forth in a friendly spirit about various things.

Reflecting on those times, Fukasawa spoke as follows:

"Hitachi is a company that bears considerable responsibility in supporting the infrastructure of Japan. As my interests turned to products that were indispensable to our ways of living, I began to think about how we should implement them in society. This led to expressing my wish to try working together with Hitachi on elevators."

Out of this conversation was born the “HF-1” elevator concept model in 2015. This was followed in April 2019 by development aimed at a standard elevator that could be implemented in all kinds of buildings.

The effects of the COVID-19 pandemic that erupted in 2020 extended also to design. According to Fukasawa:

"Although I missed being able to meet up with people, I came to realize that it was possible to work efficiently using remote conferencing and the like. I think that the idea of the 'new normal,' that is, carving away at waste and living easily, swelled up inside of me and wound up reflected in products."

Continuing improvements and an annual sales target of 5,000

Hitachi’s new standard elevator began sales in April. According to Hisatake Yanagisawa of Hitachi Building Systems’ Marketing Division, architectural firms and general contractors have responded that it is "simple and elegant" and "very handsome in its pure white."

Yanagisawa said that with the installation of the first elevator completed in September and with more shipments scheduled in the future, the launch of sales has been a success. Elaborating, he continued:

"Due to the success of the design, we are considering expanding this new model design to other models. While continuing to make improvements to the hardware, we have set a target for annual orders for all elevators at 5,000 units."

Looking back on Hitachi’s new standard elevator development, Fukasawa spoke as follows:

"Raising quality of life does not mean improving the economic power of the individual. Rather, it involves the things that everyone uses getting better. I think that is what will become the standard. Through the development of the new model, I was able to experience that we had created the standard of elevator for such an era."

-

1"nanoe" and the "nanoe" mark are trademarks of Panasonic Corporation.

-

2LINE and the LINE logo are registered trademarks of LINE Corporation.

-

3A maintenance contract with Hitachi Building Systems Co., Ltd. is required.