What are the New Challenges and Their Solutions for the Increasing Number of EVs and Batteries?

Feb. 6, 2024

Xin Luo

As the number of electric vehicles (EVs) on the road increases, so does the number of batteries that power them. This has brought with it a variety of problems, such as a lack of charging stations, vehicles that could stop running suddenly, and how to treat batteries after they degrade. This article will highlight the issues related to battery life cycle and the solutions proposed by the Hitachi Group.

Expanding the charging infrastructure

Although the number of EVs continues to increase in these days, the number of charging stations is not enough to cover and satisfy the needs of EV users.

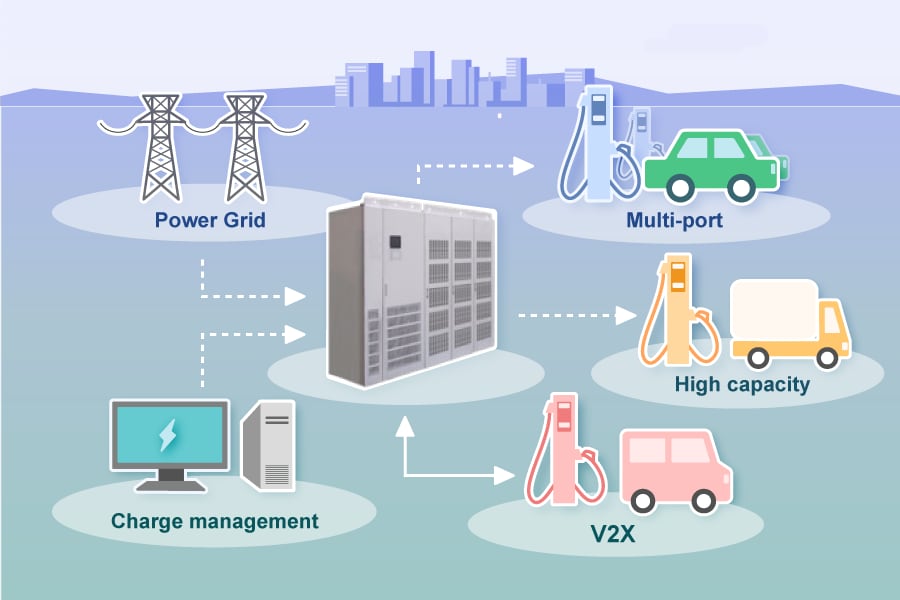

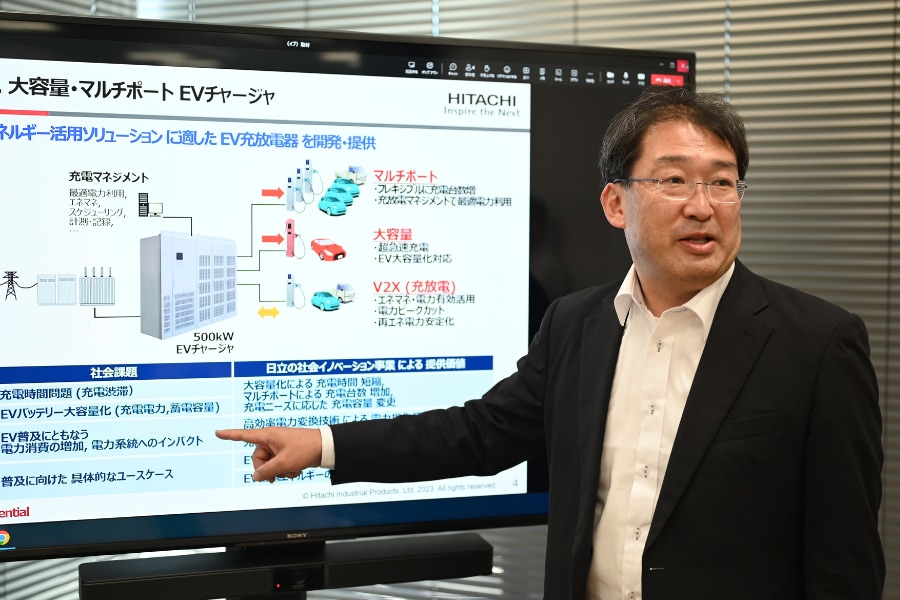

The Multi-Port EV charger newly developed from Hitachi Industrial Products solves this problem. The EV-Port charger’s main feature is that the various output configurations can be arranged depending on various needs for charging EV within a maximum capacity of 500 kW, such as 20 ports of 25 kW outputs, 10 ports of 50 kW outputs, or a combination multiple capacity outputs. It also supports fast charging and V2X (an abbreviation of vehicle-to-something, the function to supply power from EVs through EV charger, such as vehicle-to-home [V2H] and vehicle-to-grid [V2G]).

In addition to being used to charge commuting vehicles at workplaces, the Multi-port EV charger is expected to be installed in facilities including tower block, large buildings, logistic depots of transportation companies that operate large number of trucks/buses and so on. Comparing with multiple installation of conventional type of EV chargers, footprint of the Multi-port EV Charger is smaller for the same capacity.

Hiroaki Miyata, Senior Chief Engineer at Hitachi Industrial Products, said: "The Multi-port EV charger is designed not only for simple charging, but also for efficient energy use with energy management. For example, when installed in a factory parking space, the Multi-port EV charger will manage ideal charging power at appropriate times depending on power consumption of the entire facility and the status of renewable power generation. Moreover, if electricity demand becomes tight, electric power discharged from EVs is expected to assist to support factory operations.”

The Multi-port EV charger will support the charging infrastructure to cover for the increasing number of EVs. As well, in some cases using EV batteries as a new distributed power source with the chargers can help for effective energy uses and power grid stabilizations. In short, it is an attractive solution that contributes to achieve carbon neutrality from multiple angles.

Remote diagnosis of battery deterioration status

The batteries used in EVs are lithium-ion, and like the batteries used in smartphones, they gradually degrade as they are repeatedly charged and discharged. As the battery degrades, the vehicle will no longer be able to travel the distance that it could when it was first manufactured.

However, determining the condition of a battery is not easy. For example, there are business operators that manage a number of EVs, such as buses and trucks, and for those business operators, it is time-consuming to load and unload the battery on each EV one by one to diagnose the battery’s condition. To eliminate this time-consuming task and improve convenience, Hitachi High-Tech has developed a solution to remotely diagnose the degradation of a lithium-ion battery.

The remote deterioration diagnosis solution analyzes battery-related data such as temperature, current, voltage, date and time transmitted from EVs once a day on the cloud of the Hitachi High-Tech's system, and automatically calculates the degree of deterioration as "~%".

If the degree of deterioration can be easily and quickly determined, it will not only be useful for daily operation and maintenance but also for detailed planning to replace EVs and batteries. This allows business operators to operate a large number of EVs with peace of mind.

In anticipation of internal-combustion-engine-powered vehicles being replaced by EVs, Hitachi High-Tech has been conducting proof-of-concept and proof-of-value demonstration of a remote lithium-ion battery diagnostic solution in China for several years, calculating the battery status of about 6,000 vehicles every day. Yosuke Kido of Hitachi High-Tech, who is promoting the project, said passionately: "We have improved diagnostic accuracy by diagnosing a cumulative total of tens of thousands of different vehicle models. We are aiming for commercialization in FY2024."

Kido also explained the appeal of remote diagnosis: "EVs are not the only technology that uses lithium-ion batteries. Due to environmental considerations, lithium-ion batteries are also expected to be used to power agricultural machinery, such as tractors, and ships operating in inland sea. Remote diagnostic solutions have the potential to support the electrification of various vehicles used in society by maximizing battery lifetime value, reducing environmental impact, and providing other value."

Reusing model for EV batteries

What happens to the battery in an EV when it degrades? The EV will no longer be able to travel the several hundred kilometers listed in the sales catalogue. However, a battery removed from an EV can still be used for other purposes.

To collect these Second Life batteries and find a new use for them as storage batteries, Hitachi developed the "Battery Cube." Measuring approximately 2.3 m high, 2.2 m wide, and 4.6 m long, it is round and has wheels. It looks cute and has as many as three EVs' worth of used batteries inside. Depending on the combination of used batteries, each Battery Cube has a capacity ranging from 25 kWh to 50 kWh and can charge and discharge at 6 kW to 10 kW using V2H.

Because the devices can be loaded onto a truck and transported, they can be set up in the parking lots of convenience stores and other retail locations. Hitachi has set up several Battery Cube devices at a Seven-Eleven Japan convenience store so as to conduct a trial to explore how storage batteries can be used. Specifically, the trial involves storing electricity generated by renewable energy sources, such as solar panels, during the day and supplying the stores with electricity at night.

Additionally, Hitachi is also conducting a trial in collaboration with Mitsubishi Motors to use a Battery Cube device as a backup power source to operate elevators so as to see whether the device is a viable option as an emergency power source in the event of a disaster.

Hitachi is aiming to commercialize the Battery Cube in FY2024. "We will continue to make improvements to make the product even smaller and easier to set up when we commercialize it. We believe that we can contribute to realizing carbon neutrality by using EV batteries for more than one application and in a variety of situations," said Koichi Hiraoka of Hitachi.

But then, what happens to used batteries that have been repeatedly charged and discharged by the Battery Cube device and further degraded? In cooperation with automakers and recyclers, Hitachi plans to extract lithium, cobalt, nickel, and other rare metals from the batteries for reuse in the production of batteries once again. By recycling and reusing limited earth resources for the benefit of future generations, a sustainable society and economy is becoming closer to reality.

The Battery Cube was also be exhibited at the 28th Conference of the Parties to the United Nations Framework Convention on Climate Change (COP28). For more information, please click here.