Digital Twin: What Does This Mean and How is Hitachi Using This Technology?

Mar. 28, 2023

Yuichi Yamagishi

As digital transformation (DX) becomes more widespread, the use of data is becoming ever-more important. Meanwhile, the amount of data continues to grow, and more data than humans can imagine is being generated around the world every second.

Is it possible to visualize and intuitively handle vast amounts of data in an easy-to-understand manner? A new technology called "digital twin" is expected to help solve this problem. This article will explain the meaning and benefits of a digital twin, as well as examples of how Hitachi uses the technology and the solutions that it has developed, in layman’s terms.

What is a digital twin?

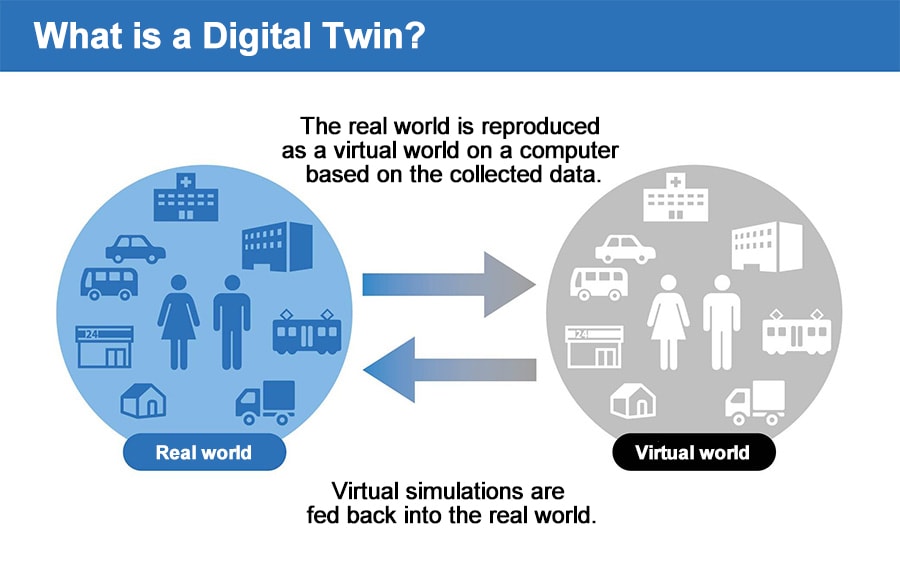

Although the definition of "digital twin" varies widely by business field and industry, it refers to "technology that reproduces the real world in a virtual world on a computer based on data collected in the real world."

In recent years, technologies, such as the Internet of Things (IoT), which uses sensor devices and image recognition AI, have evolved dramatically. These digital technologies have enabled data to be collected and to create, as the name suggests, a "digital twin" in a virtual space on a computer, where reality can be reproduced and simulated.

Its applications are wide-ranging. The following are some examples:

- Digital twin that reflects real-time information on urban spaces, movement of people in the city, weather, etc.

- Digital twin for simulating disaster areas

- Digital twin for plant production line design

The droplet simulation images comparing mask-wearing and non-mask-wearing shown in the news in the early days of the COVID-19 pandemic and 3D images of the inside of the body from an MRI are also digital twins in the broadest sense. The point of both images is to "visualize complex phenomena and data so that they can be understood intuitively."

Difference between Digital twins and the Metaverse

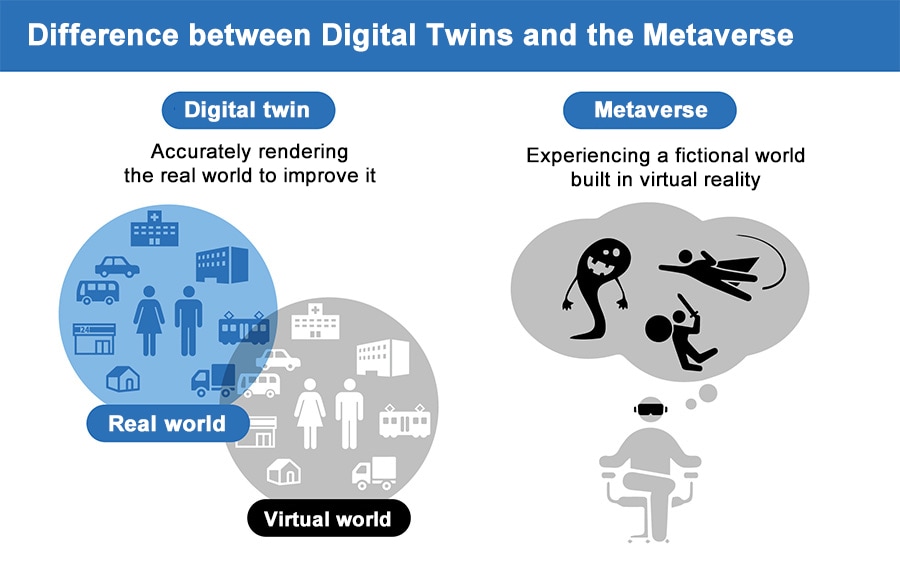

Conversely, the "metaverse," a virtual world developed in a three-dimensional (3D) space, has been creating a buzz in recent years. Both digital twins and the metaverse are similar in the sense that they are technologies that utilize a virtual world digitally.

However, the metaverse does not necessarily have to be a faithful reflection of the real world. Creating a fictional world that cannot exist in reality, for example, people flying in the sky or fighting monsters with weapons, is also considered a part of the metaverse.

On the other hand, a digital twin is significant in that it is a copy of the real world. The objective is to correctly understand what is happening in the real world while utilizing a virtual space to maintain and improve the real world. This is the role required of a digital twin.

Benefits of creating a digital twin

The benefit of creating a digital twin is that it can accelerate operational efficiency and transformation by making complex data visible and helping make issues easier to discover.

The following are the three main situations in which the benefits of this system can be used:

- When you want to know the structure of an object, such as a building or distribution route

- When you want to understand the current situation

- When you want to simulate the behavior of an object or person

As a digital twin makes information easier to ascertain, it can be easily understood and decisions can be made quickly and accurately, even by non-experts skilled at reading data.

Why is it making waves now?

The truth is that concepts similar to digital twin technology have existed for more than 20 years. In recent years, however, the development of technologies and sensors that handle data, such as IoT, AI, and robotics, has brought renewed attention to the digital twin concept.

Moreover, all industries are undergoing DX—the essence of which is how to utilize data to enable high-quality decisions on improvements.

Therefore, a process is essential to convert real-world objects, people, and other phenomena into data, link them together, extract the important elements, and visualize them so that they can be understood intuitively. In the age of DX, the digital twin is truly the key to solving issues by leveraging data.

Usage example of a digital twin

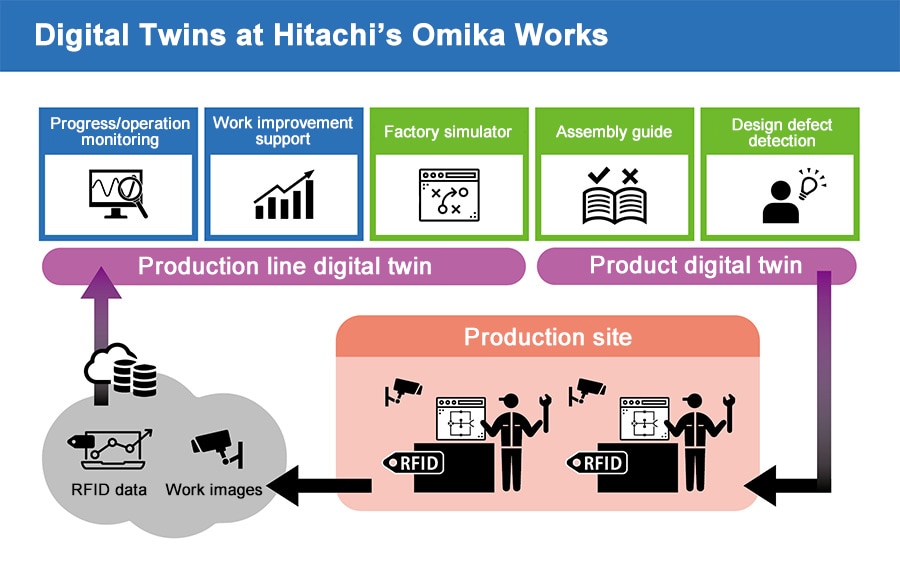

Industrial applications for digital twins have already begun. For example, Hitachi's Omika Works, a location marking the first time that a Japanese company has been selected by the World Economic Forum (WEF) as a "Lighthouse," is an advanced factory that can help lead the fourth industrial revolution, and it is using digital twins in its manufacturing facilities.

About 80,000 RFID tags (a non-contact system that can identify, manage individual information on people and objects) and about 450 RFID readers and video cameras have been installed at the plant, which designs, develops, and produces software and hardware for information control systems, such as factory progress management, to automatically collect data on the flow of people and objects at the production site.

This has enabled a digital twin of the production line to be built that visualizes, with data, the flow of people and objects on the production line. This information is used to monitor the progress of production, improve quality, and automatically detect equipment defects. As a result, the plant has successfully reduced the lead time (time taken from the start of production to shipment) of flagship products by 50%.

Furthermore, Omika Works also takes advantage of digital twins outside the production site. The train operation management system developed by Hitachi automatically gathers the necessary information on the location, speed, and number of passengers for all running trains and maps this information on a monitor to instantly ascertain the operational status at a glance. This visualization in conjunction with the operation system is truly a "digital twin."

Therefore, we can see that a digital twin is powerful in visualizing the status of systems that are difficult to understand intuitively due to their large scale, such as large plants and social infrastructure such as railroads.

Growing expectations for digital twin technology

Digital twin technology is being exploited in many other fields that require data-driven problem solving, such as in reducing CO2 emissions from production activities at industrial facilities and in security measures to combat cyberattacks.

It is precisely in these large-scale issues that we need to utilize open-source digital twin technologies to efficiently solve problems, rather than aiming for solutions based on the knowledge of a single company alone.

If IoT, AI, and robotics for data utilization continue to develop and the amount of data that can be obtained continues to increase, a virtuous cycle will be created that will make it easier to introduce digital twins. In the future, it has also been predicted that an era will arrive in which visualized data will be used to optimize operations through AI and other means.

The industrial implementation of digital twin technology will be increasingly sought after, further raising expectations.

(Supervising editor: Naohiko Irie (senior strategist), Control System Platform Division, Social Infrastructure Systems Business Unit, Hitachi, Ltd.)