Gaining Business Value and Improving the Environment Through Fleet Intelligence

By Steve Chaffee, Director, Transportation Big Data, Analytics and IoT Solutions, Hitachi America, Ltd. and Adriano S. Arantes, Ph.D., Senior Research Scientist, Industrial Artificial Intelligence Lab, Hitachi America, Ltd.

Our society depends on safe and reliable transportation. But traditional commercial trucks are increasingly expensive to purchase and, due to their growing complexity, difficult to maintain and keep on the road. Along with the cost of ownership, the consumption of fossil fuels has added exponential cost to their operation – as well as increasing concerns about their impact on the environment. Fleet management is at a critical crossroads. Fortunately, new technologies are being developed and adopted to address these issues.

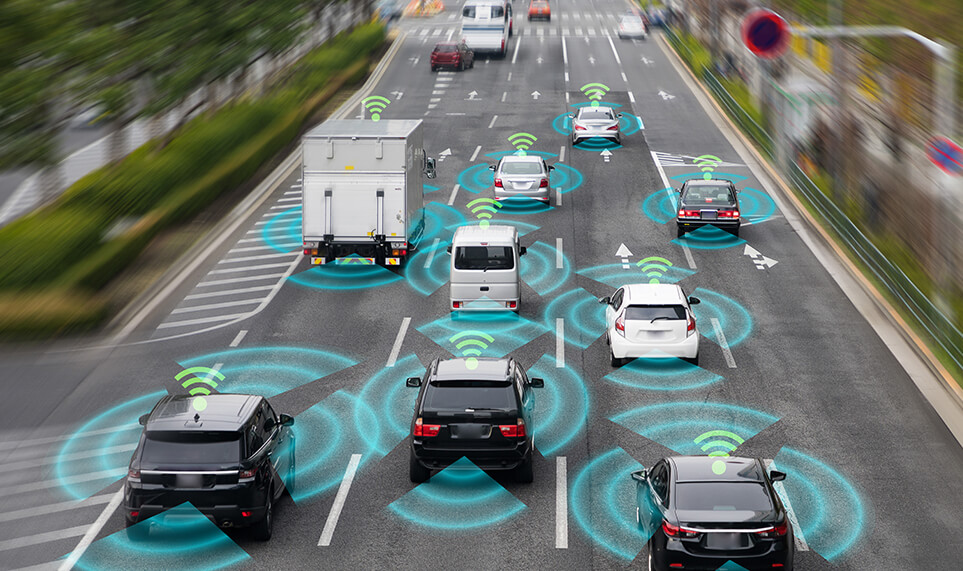

As it turns out, fleet management is highly suited to the internet of things (IoT). New commercial vehicles have both built-in IoT edge sensors and cloud connectivity. Together, these are sources of real-time data that organizations can collect to optimize their operations. For example, IoT can be used to locate vehicles and manage fleets, track driver performance and progress against prescribed routes, remotely monitor vehicle speeds and condition, and recommend prescriptive and predictive maintenance.

Forward-thinking fleet organizations actively exploit IoT to help them make faster, more efficient decisions. And there is a growing performance gap between those who exploit the available IoT and those who don’t. For example, according to McKinsey, business-to-business (B2B) companies in the top quarter of digital adopters achieve five times the amount of revenue growth versus their competition, and 8 times the operating profit of laggards over five years.1

We’re now ready for the next phase in this evolution: fleet intelligence. Fleet intelligence extends the foundational advantages of the Internet of Things (IoT) and seamlessly integrates analytics, artificial intelligence (AI) and machine learning (ML), ushering in a new era of unparalleled benefits for commercial fleet operators. The urgency to harness fleet intelligence is underscored by its transformative potential. In a highly competitive market where staying ahead is key, integrating advanced digital technologies is not just an option, but a strategic imperative for building more sustainable fleet management systems.

Fleet intelligence acts as a multiplier that increases operational efficiency, cost-effectiveness and strategic decision-making.

The compelling reasons to embrace it now go beyond the immediate advantages – they speak to the foresight required to build a fleet that is not only responsive to the challenges of today but also resilient to the uncertainties of tomorrow's modern transportation landscape.

Trucks are expensive to purchase, operate and repair. New sleeper cabs with trailers cost in excess of $170,000 to purchase and $180,000 a year to operate, including fuel costs of $70,000.2 Truck-tractors are driven an average of 7.6 years or 695,000 miles before they need to be replaced.3 That makes reducing fuel costs, avoiding breakdowns and extending truck life spans through proactive maintenance a very high priority for fleet operators.

The number of technicians who are retiring has increased, and the number of younger skilled technicians entering the workforce has not kept pace. The industry needs 67,000 technicians to replace retirees and 75,000 new hires to meet demand by 2022.4 Companies can help address this shortfall by training new staff and leveraging skilled technicians’ time better with analytics-driven diagnostics.

Today’s telematics are just a start. With IoT, digital platforms and partnerships with high-tech innovators, fleet operators can integrate more data than ever from a variety of sources, including road video, real-time weather and congestion data, driver and truck performance, and more. All this data creates a holistic picture of trucking conditions that managers can use to improve fleet operations as well as driver and public safety. For example, the ability to optimize routes in real time helps truck drivers avoid slowdowns, reduce mileage and minimize left turns, which in turn decreases idle times and fuel consumption.

Providing right-time maintenance is the key to optimizing vehicle uptime. Through predictive maintenance, fleets can be kept in a strong operating position all the time – and that’s essential as customer transportation demands and regulatory requirements both increase. Maintenance is expensive, and maintenance that is performed too often, not often enough, or incorrectly is very expensive. By using the data that is available and applying advanced analytics, organizations can avoid excessive costs by engaging in predictive and prescriptive maintenance and implementing recommendations based on real-time data.

Looking to the future, the trucking industry is fast evolving as advances in powertrain, automation, connectivity and miniaturization expand the use of electric trucks.5 For example, Tesla announced an electric semi to great media buzz, Volvo Trucks is investing in electric trucks, and Daimler Trucks is testing them with customers. Electric trucks will reduce the industry’s dependence on fossil fuels, reduce emissions, and meet state mandates for lower or no emissions, such as California’s Advanced Clean Truck Regulation.6

Companies that can pair AI advances with electric truck technology can transform the cost basis of their business, stay compliant with regulations and become leaders in environmentally responsible business practices.

With any emerging technology, the early adopters have a huge advantage over their competition,7 and it is likely that your competitors are already adopting new fleet management technologies. So what is the path forward with data analytics and AI?

Although your company is likely collecting a wealth of data, you don’t need to analyze all of it. Understand which data ties to high-value business processes, and use analytics and AI to improve those processes. Build on your success by linking related processes, creating greater transparency and adding iterative gains over time.

If you haven’t adopted preventive and predictive maintenance yet, you should. Predictive maintenance using vehicle telematics can generate automated maintenance alerts, enabling managers to plan routine maintenance, align inventory on hand with service needs, service vehicles promptly, and identify staff training needs. Benefits include reducing downtime and costly break-fix incidents, such as engine replacements that can occur when trucks aren’t maintained properly. Prescriptive maintenance takes this a step further by determining the likelihood of certain actions and recommending fixes, enabling managers to balance the ROI of upfront investments against fewer service incidents.

Mobile networks, satellite positioning, sensors and onboard computing enable real-time monitoring of drivers and vehicles, generating data that companies can aggregate with the data from their management systems. Advanced fleet intelligence uses all this information to help managers optimize every aspect of fleet management, including contracts; vehicle acquisition, operation, and depreciation; driver management and retention; and, of course, maintenance. Analytics models learn and adapt over time, continually enhancing performance.

The future of trucking is exciting, as fleet management becomes fleet intelligence – a precision science that is continually fine-tuned with the latest data and analytics. Those who lead with AI now will be well-poised to capitalize on next-generation technology in efficient trucks, including electric trucks. In addition, managers will increase profitability through operational optimization while enhancing the safety and security of drivers, cargo and the public and reducing environmental impact. Indeed, as fleet managers implement predictions and recommendations gained through advanced fleet intelligence, the transportation industry will be well-positioned to have a significant and positive impact on the environment and society as a whole.

The shift towards a net-zero future is indeed a tangible result of embracing advanced fleet intelligence technologies and their transformative impact on the way we move goods, ensuring a greener, safer, and more sustainable tomorrow.

When you’re ready to investigate fleet intelligence for your own fleet, consider partnering with a company that has deep industrial and logistics experience; expertise in analytics, AI, and operational technology (OT); and a commitment to powering good in the world. With your wealth of data and your partner’s expertise, the road to your fleet of the future will be wide open.

Learn more about the benefits of fleet intelligence for your business.