By Tyler W. McCoy, Chief Engineer at JR Automation

Take advantage of advances in warehouse automation ― including advanced robotics ― to create flexible, robust supply chains that can keep up with increasing customer demands. A radical shift in consumer behavior accelerated by the COVID-19 pandemic has exponentially expanded the wide-scale adoption of e-commerce and online purchasing. As consumers increasingly make online purchases for standard items like groceries and household supplies, this shift is likely to become permanent ― creating a significant impact on warehouse operations and creating new opportunities for innovation.

Early winners so far in this business environment have been the technology-embracing early adopters such as Amazon and Ocado, who have innovated with robotics and software to create more efficient, durable supply chains. However, there’s room in this space for all players who are prepared to adopt warehouse automation and robotics. It’s likely that those who don’t participate in this disruptive innovation risk being left behind.

Traditionally, robotics have been applied in repeatable, fixtured applications, such as those on automotive assembly lines. Now, artificial intelligence (AI) and the Internet of Things (IoT) are enabling breakthroughs in perception and complex decision-making in real time. Next-generation robotics intelligence combines cutting-edge robotics, artificial intelligence and data analytics to create a connected ecosystem that can seamlessly collaborate with the human workforce. This allows robotics technologies to operate effectively in more complicated, unstructured environments such as the warehouse and distribution networks.

Due to the inherent modularity and scalability of robotics systems for picking, sorting and palletizing, organizations of all sizes can reap the benefits of these innovations while making warehouse operations more efficient, cost-effective and safe. The ability to add robotic solutions with a high return on investment (ROI) intermixed with manual processes make them ideal candidates for investment in existing manual facilities.

The rise of e-commerce has stressed existing parcel and distribution networks to their limits. Faced with a huge need for the efficiencies and increased capacity that warehouse automation can fill, a new breed of intelligent robotics solutions have started to go mainstream.

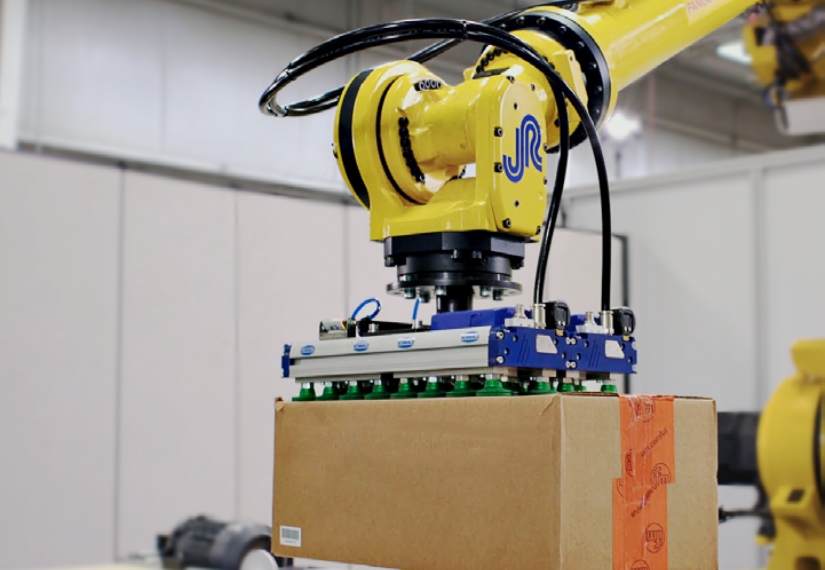

Palletizing robots, for example, efficiently automate labor- and time-intensive tasks in distribution and order fulfillment, helping to increase productivity and gain a competitive edge.

The numerous benefits and scalability of these solutions makes them a good fit for an industry that is still mostly manual, and they are a logical next step. For many enterprises, warehouse automation technology adoption is lagging significantly or absent altogether. According to DHL research, 80% of warehouses remain manually operated.1 Another recent survey indicates that the greatest investments to date are in conveyance (63%), while robotic palletizing and picking are still very low (15% and 8%, respectively).2

Major e-commerce companies know that nimble, automated supply chains are key to meeting demand and staying ahead of the competition. To keep up with these major players, smaller and emerging e-commerce companies must take the right steps to automate their warehouse supply chains too.

Prior to the pandemic, e-commerce and logistics were geared toward the peak season (early November through January). Distribution networks would ramp up for peak, then struggle with underutilized capacity for the remaining nine months. In 2020, the peak began in mid-March and hasn’t slowed. The challenge now for many smaller enterprises is how to innovate and grow within a peak environment that never subsides. Enterprises no longer have the luxury of a downtime during which to upgrade facilities to increase capacity and integrate new technology.

The e-commerce giants have an easier time integrating robotic warehouse automation technology organically because their technology stacks are already built. Smaller enterprises must work to bridge this chasm. One of the advantages of advanced robotics is that it can be integrated into operations without taking down a system or facility. Robotics can be added little by little, in a modular fashion, without major disruptions.

There is a significant need among both types of businesses for a partner and integrator that can develop, productize and scale solutions across the entire distribution network.

Together, Hitachi and JR Automation (which was acquired by Hitachi in 2019) work with customers to co-create the products and robotics they need to solve supplier challenges — and then bring an entire team to deploy at scale. This is achievable for large enterprises as well as smaller industry players.

Combined, Hitachi and JR Automation bring deep cross-industry expertise in integrating fundamental robotics technologies into a variety of use cases, including e-commerce warehouse operations. JR Automation has been very successful at executing hundreds of vision-guided robotics solutions in the warehouse and logistics space. Vision-enabled solutions recognize and adapt to the high mix of materials to be handled and are able to make decisions in real time on appropriate picking strategies.

By leveraging their scale, JR Automation and Hitachi have developed a distinct high-volume deployment business and are now uniquely positioned to both develop and refine the initial system designs while deploying at scale. For one customer, we have deployed over 150 robotics solutions into a warehouse environment over the course of two years.

The challenge for every enterprise is how to make these technologies work to meet the specific needs of the business. By combining the operational technology expertise of JR Automation with Hitachi’s core strengths in IT infrastructure, and advanced digital technologies such as AI/ML and data analytics, we provide a digital thread that enables you to analyze your enterprise resource planning (ERP) for your entire supply chain. With this analysis, you can truly understand inventory and supply chain risk, and then optimize warehouse operational technology to best fit your requirements.

Your starting place is right where you are. You don’t need to have all the answers. We can craft the right problem statement and the best solution for you so you can begin your robotics journey early and define your best first moves. We help you create a custom holistic solution that addresses your challenges and provides insights across your IT and warehousing infrastructure so you can drive continuous improvements.

Robust supply chains are critical infrastructure. The COVID-19 pandemic has made that abundantly clear. Every nation must have a disaster-ready supply chain that meets every day needs and is also capable of responding quickly to any emergency. Hitachi’s goal as a technology supplier and integrator is to power social good for the world by helping enterprises put these types of supply chains in place so they are well-prepared to address any situation. Robotics technology is the future of warehouse and logistics automation supply chains. Your business can be made supply chain–ready now.

Learn more about JR Automation and warehouse logistics and automation.

Chief Engineer, JR Automation

Tyler McCoy is an experienced engineer and business leader in industrial automation. He leads the strategy and new product development initiatives at JR Automation for the warehouse and logistics industry. Over his 15 years in the automation industry, he has delivered solutions to e-commerce, automotive, aerospace, electric vehicle, consumer electronics and back-of-restaurant automation customers.

He currently serves on the board of directors for the Robotics Industries Association (RIA) and on the Strategic Advisory Committee on Artificial Intelligence for the Association for Advancing Automation (A3). Tyler holds a BSME from Grand Valley State University and an MBA from the University of Notre Dame.