By Rajesh Devnani, Vice President, Digital Solutions Division at Hitachi Vantara and

Justin Bean, Global Director of Smart Spaces Marketing at Hitachi Vantara

The COVID-19 pandemic has challenged every part of our global society, but it has especially attacked our sense of safety in the places we once felt the least worried — among friends and family, at the grocery store or in the park, and at work. A strong economy suddenly feels fragile in the face of unexpected disruption. And while organizations have always needed to take workplace health and safety seriously, the crisis has created a whole host of new workspace risks to mitigate and manage, and it has revealed operational and supply chain risks that were unseen before. As we face the potential of multiple “next waves” while we return to our lives, how can organizations face these challenges and maximize the chances of greater well-being for employees, customers and community?

The road to recovery and resilience begins with great ideas paired with great technology to create and implement a strong risk-reduction strategy that will continue to protect your organization and its people for years to come. We live at a time when an explosion of digital capabilities, such as interconnected smart devices, internet of things (IoT) data, predictive analytics and machine learning solutions has transformed all aspects of business. Now, these same tools built into smart spaces technology can help reduce risk and safeguard your workers through a multilayered approach of mitigation, containment and reporting. At Hitachi, this helps drive what we call social innovation — powering good to return us all safely to the places where we work, travel and play.

Workplace health and safety has always been a strategic imperative for manufacturing organizations due to its critical significance for human life and well-being, potential legal ramifications and reputational implications. That was even before COVID-19 struck. COVID-19 elevates the strategic relevance of workplace health and safety further. It also necessitates the adoption of a comprehensive enterprise risk management (ERM) framework, backed by a suite of digital solutions, to mitigate potential COVID-19–based adverse impacts and get employees back to the shop floor — in a safe and secure manner.

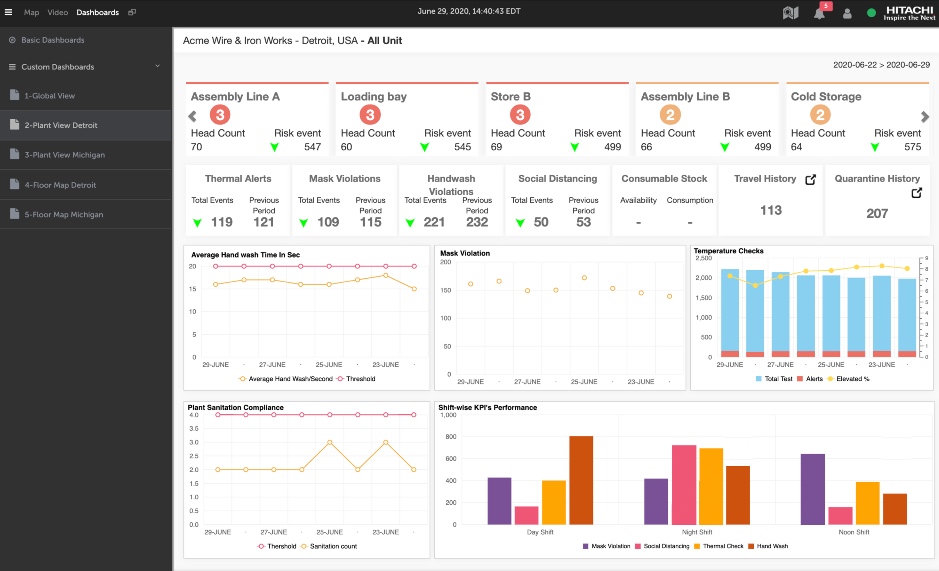

A holistic risk management framework with a multidimensional perspective made up of worker, work site, societal, and compliance risk aspects is essential. An ERM strategy is the only way to objectively measure and quantify workplace risk levels, expedite mitigation measures, and most importantly, build confidence with employees and communities at large. The framework needs to be complemented with a digital suite that can support measurement and analysis of critical aspects associated with personal protective equipment (PPE) and hygiene compliance, social distancing, contact tracing, thermal scanning and more.

Any efforts to reduce risk must start with a strategy that not only determines how COVID-19 will be dealt with, but how the risk-reduction strategy aligns with the broader goals of the organization. Point solutions abound in today’s world, but end-to-end solutions that are aligned with end-to-end strategies will separate companies that thrive in the coming years from those that falter and are left behind.

Today’s technologies have helped create “smart spaces” that improve the safety, operations and experience of workers, customers and passengers. These types of solutions have been adapted to address emerging needs and new use cases and are now being adapted to solve the challenges of worker health and safety, including reducing risks related to COVID-19. This will be a significant part of getting organizations of all kinds back to business. Here are some examples of those technologies and how they can be used.

High fever is one of the most consistent symptoms of COVID-19 infection, and it’s important to have fast, accurate body temperature detection to identify potential cases and prevent wider spread. But manual temperature checks can be invasive, slow, labor-intensive and impossible to scale. Additionally, they put the temperature-takers at risk.

Picture yourself on the subway platform during your first post-pandemic commute, or on your factory floor overseeing multiple shifts of workers. Large groups of people are flowing in and out of shared spaces. Thermal scanning technology can replace manual checks in these crowds to help you quickly flag individuals with elevated temperature. This is a nonintrusive and more efficient way to select people who need additional health screening and ensure that they aren’t ill or putting others at risk. It also alleviates the risk to healthcare workers who would otherwise be testing large crowds of people at close range.

Although people are doing their part to fight COVID-19 by socially distancing at the workplace, reopening work environments is predicted to lead to second and successive waves of infection and put a strain on our ability to coexist while maintaining a constant safe distance. But it doesn’t have to. 3D Lidar technology seamlessly collects and integrates granular, continuous information to give you a 360-degree view of what’s happening in your environment and is designed to not collect personally identifiable information (PII). This data then uses a solution such as the Hitachi Visualization Suite to generate real-time geospatial and graphical analytics to determine where social distancing is working and where it isn’t.

In the effort to reopen society, this information is powerful in its potential for impact. Operational managers, regulators and policymakers can use three-dimensional data to target educational programs to areas where social distancing is a challenge. Warehouses, manufacturers, retailers and transit authorities can also use these tools to redesign the physical spaces people move through to help them maintain distance. Imagine a shopping experience guiding you safely to exactly the goods you came to purchase, or inventory specialists working in a fulfillment center designed help them do their jobs with greater accuracy, efficiency and confidence — all while keeping them safer.

The impact goes beyond the workplace. Pulling in data from other sources in the community can help isolate risks and provide more targeted prevention planning. It’s all a part of being a good citizen as well as a good employer.

Another way COVID-19 has amplified risk is by turning every piece of equipment, every cafeteria table and every doorknob into a possible disease vector. Employers will need to have a strong plan of attack for maintaining a clean environment. One of the most effective ways to keep surfaces cleaner and employees safer is to promote and enforce rigorous handwashing.

3D Lidar can help there, too. Its machine-learning engine detects proper handwashing behavior, tracking things like the use of soap, the duration of washing, and whether a clean paper towel was used. This data can be analyzed to show which restrooms, facilities or locations are doing the best (and worst) at handwashing, so that managers can emphasize training and policies in the right places to have the most impact. This promotes a more sanitary environment and raises your staff’s overall awareness — something they can take home to their communities outside the workplace.

Best of all, 3D Lidar collects and analyzes this information anonymously, without collecting private information, which is essential for restrooms, hospitals and other areas where the need for privacy is critical. This protects the privacy of your employees and offers another kind of safety — peace of mind.

Social innovation — and the related digital innovation — isn’t just a temporary fix for this unique circumstance. The virus may have been the catalyst for a new, data-driven approach to worker health and safety, but the solutions can be a technological foundation you can build on to continue improving the safety and wellness of everyone in your environment.

Tools like Lumada Video Insights can leverage video intelligence, 3D Lidar and other data to automatically monitor the use of masks, helmets and other PPE without slowing down productivity. You can use this information to help focus your training and communication strategy on the most effective uses for protective gear, reducing injuries, saving time and costs, and protecting people’s health. Sensors on forklifts or other dangerous equipment can be used to help your workers avoid collisions and accidents. You can also use insights from video analytics to manage evidence associated with cases to help in more effective incident response, to facilitate insurance and workers’ compensation claims, and to plan policies for the future.

Preventing injury isn’t just the right thing to do, it’s also the prudent thing for your business. Workers’ compensation claims, time lost to injury, and redundant training are all among the highest costs for many industries. Leveraging smart technology creates the foundation for reducing the injuries that can cost people their livelihoods and companies money that could be better spent on growing business and ensuring job security for your employees.

Creating a safe and healthy workplace sets off a chain reaction that leads to a safer and more prosperous world for all. Having the right information to measure, communicate and mitigate risk creates a plan for the unexpected, so it can make your organization stronger, less fragile and more resilient. The COVID-19 pandemic seems to dictate so much right now, and the way companies reopen will set a vision for the future.

As you and your business prepare to safely reopen, be sure you understand how quickly you can respond and adapt to new safety concerns to maintain a healthy environment amidst constant change. You’ll need to fully comprehend your shift patterns and work allocation to achieve maximal productivity while ensuring compliance with requirements such as social distancing. Ideally, you will have an answer for these questions, along with a future-proof strategy to ensure safety in your factory, offices or workplace:

• How quickly and effectively can you identify and isolate symptomatic workers while minimizing operational disruption, and what is your remediation process?

• What is your plan for sterilizing potentially infected equipment and physical spaces?

• How will you transparently communicate your safety strategy, so that your employees have the information they need and feel confident that you are protecting them and their families?

• Do you have the right technology in place to capture, report and utilize meaningful data for better decision-making and policy? If not, how are you objectively quantifying safety and operational risks and ensuring a rapid response for emerging risks?

• How do your COVID-19 response plans and technologies help advance your broader health, safety and environmental objectives, as well as support the broader strategic objectives of your organization?

• How can you turn the current crisis into an opportunity for accelerating adoption of digital technologies and automation, which will provide competitive differentiation in the long run?

Finding the right answers gets everyone back to doing the things they value. With comprehensive Digital Health and Safety solutions you can manage shop-floor safety, build an effective Health, Safety & Environment strategy, and avoid incidence costs and litigations. You can do better work, create better products and solutions for your customers, do your part to strengthen the economy, and contribute to a more sustainable world — and Hitachi is ready to help. We’re all in this together like never

before. Let’s power good together.

Vice President, Digital Solutions

Rajesh Devnani leads the industry Practices & Digital Solutions Presales function at Hitachi Vantara. His charter is delivering differentiated world-class digital solutions, leveraging the best capabilities of Hitachi Group across digital technologies and comprising cloud, IoT and data science/analytics backed by a strong industry domain and consulting capability in manufacturing, transportation, energy and healthcare.

Rajesh’s background includes 22+ years of industry experience across large ERP programs, business consulting and digital transformation engagements. He holds multiple professional certifications including CSCP and multiple SAP certifications. He is a speaker at multiple industry/professional forums and is also a blogger on key technology topics.

Global Director, Smart Spaces and Lumada Video Insights Marketing

Justin Bean is the global director of Smart Spaces and Lumada Video Insights marketing at Hitachi Vantara, which brings IoT solutions to market with the mission of social innovation. Justin has worked with Silicon Valley startups and Fortune 500s that are applying IoT and other disruptive technologies to improve our lives and cities. He has worked in the U.S., Japan and South Africa on projects that include smart cities, smart parking, electric vehicles, renewable energy, machine learning and 3D printing. He was the recipient of the THINK Prize from renowned innovation and design firm IDEO for their Financial Empowerment Challenge. He also served in AmeriCorps NCCC with a focus on empowering disadvantaged communities, holds an MBA in sustainable management, and resides in San Francisco, California.