“Better food, better care for our animals, better communities for our people and a better planet for all.”i These are the goals that drive Maple Leaf Foods as it seeks to become the industry leader in sustainable protein production. Canada’s largest provider of prepared meats and poultry, the company is the first major carbon-neutral food company in the worldii and one of three animal protein companies to set Science-Based Targets to reduce emissions.iii Maple Leaf Foods has roots going back 100 years, but its focus is squarely on the future.

To help achieve its goals, the company sought a technology implementation solution that could help it apply digital technology to improve operations, animal welfare and food safety. Maple Leaf Foods chose Hitachi because of its cloud solutions experience, manufacturing acumen, catalog of internet of things (IoT) products and highly collaborative approach. In addition, Hitachi is devoted to raising the quality of life of people around the world — and this type of social innovation aligns well with Maple Leaf Foods’ sustainability vision.

Maple Leaf Foods grows sustainable protein production to Raise the Good in Food - Hitachi

Every aspect of operations at Maple Leaf Foods influences its success, beginning with how animals are cared for, from receipt from the farmers through how meat is chilled, trimmed and packaged. In the food processing industry, when something goes wrong, it can set off a chain reaction with far-reaching consequences, ranging from reduced product yield to excess waste to food safety issues. The company needed real-time visibility into every aspect of operations to drive actionable insights and immediate responsiveness ― from barn to bin.

Because Maple Leaf Foods was primarily reliant on manual and paper-based processes, it lacked that 360-degree view and was limited in its ability to take swift action to resolve issues. Rapid issue resolution is crucial to keeping the production line running while assuring quality and regulatory compliance.

Delays in receiving important information and the lack of data-based insights not only negatively impact yield, food quality and safety, they can also lead to excess material waste. As an environmentally conscious company, Maple Leaf Foods considers eliminating unnecessary waste especially important in its efforts to reduce its carbon footprint.

Animal care is also a top priority for Maple Leaf Foods. Productivity, food safety and predictable yield depend on having consistently healthy animals. In addition to having visibility into activity on the plant floor, Maple Leaf Foods needed an effective way to accurately monitor the welfare of the up to 7,000 animals in the plant.

To support its goals for operational excellence and sustainability, Maple Leaf Foods sought an end-to-end digital solution that could provide real-time information across its operations and lead to:

The company also needed sensing technology and data collection methods to easily integrate with Maple Leaf Foods’ legacy systems, while providing sophisticated data analysis capabilities.

Hitachi helped Maple Leaf Foods apply multiple IoT technologies to monitor operations, provide leading-indicator warnings for potential issues and reveal other data-driven insights that contribute to operational excellence. “Hitachi brought the complete end-to-end gain in terms of professional services, technology, process understanding and the hardware implementation to give us a full turnkey solution,” said Dan Di Salvo, vice president of infrastructure for Maple Leaf Foods.

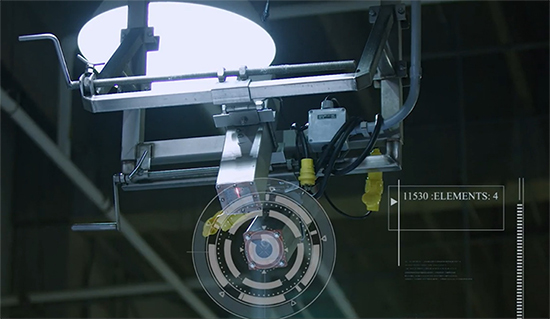

Working directly with the Maple Leaf Foods operations and IT teams, Hitachi was able to help by understanding their needs and co-creating the right solutions, including customized performance dashboards and a real-time tracker for products as they are produced. The result was a comprehensive solution on the Microsoft Azure IoT platform that includes more than 100 Hitachi wireless and 3D LiDAR (light detection and ranging) sensors and smart cameras, barcoding technology and new mobile devices for operations personnel.

With up to 7,000 animals under its care, Maple Leaf Foods can now use barcodes on pens and digital pen tracking technology to monitor every aspect of animal welfare. “We can instantly calculate the time the animals come into the pen and from there know when they need to be fed,” stated Brian Hay, Maple Leaf Foods’ senior manager of logistics and animal welfare.

Smart cameras monitor the production line to make sure processes are being followed properly and that any issues are quickly resolved. For example, the company uses LiDAR imaging technology to determine near-real-time weights of bins of meat as they’re filled. “Previously they were weighed at the end of the day and reports weren’t available until the next day,” Di Salvo said. “Now supervisors can course-correct if yields are down because equipment is misaligned or a process isn’t being followed precisely.”

Dashboards and mobile devices enable everyone to view up-to-date information across the plant floor. Production supervisors get real-time alerts when problems arise so they can respond quickly. “Communication has improved dramatically,” said Tony Lachapelle, plant supervisor for Maple Leaf Foods. “We get the right data in our hands immediately. The applications allow us to act on problems and come up with solutions much faster.”

To reduce waste and increase yield, Hitachi helped Maple Leaf Foods develop a unique real-time tracker to monitor which products are being made and when to change over to the next product. “If we overproduce, we need to repack,” Di Salvo said. “Now we can track material needs in real time and ship raw materials to other facilities as appropriate.”

Maple Leaf Foods now has a real-time view into activity across its operations, from anywhere. Its IoT tools and technology provide sophisticated data analysis and support immediate responsiveness and “predict-and-prevent” capabilities that pave the way for broad operational improvements.

“Yields and animal welfare are critical for us,” explained Jay Bashucky, plant manager for Maple Leaf Foods. “We can assess yields immediately instead of waiting until the next day to know how we’re doing. We can ensure we’re on the proper schedules to take the best care of our animals. With real-time data, we can make sure we’re doing the right things at the right times.”

By improving the company’s ability to monitor conditions and respond very quickly, the solution allows the company to gain more accurate product bin weight estimations and meat quality grading, ensures product temperature safety throughout the cooling process, supports barcoding to avoid logistics errors, and provides detailed continuous data regarding animal welfare.

The close collaboration with Hitachi gained the trust of employees, who are deeply engaged in and excited about these new capabilities. Digital tools help them maintain quality standards, minimize material flow disruptions and improve their performance. “The feedback from employees has been amazing,” said Craig Young, director of client services and integrated infrastructure for Maple Leaf Foods. “They’re saying things like, ‘This will help me make a decision today to influence tomorrow’s yield.’”

Hitachi’s digital solutions are helping to drive improvements in productivity, yields, animal care, food quality and safety, and employee morale ― all of which contribute to a more sustainable business.

This is just the beginning of Maple Leaf Foods’ transformation. The data analysis capabilities the company now has are already leading to new insights into improving process effectiveness. “We’re starting to show some positive trends in that we’re seeing things we’ve never seen before,” explained Ron Lumsdon, infrastructure architect for Maple Leaf Foods. “We’re able to do analysis on the data, which will hopefully in the long term result in improved yield ― a primary focus for us.”

With its digital transformation well underway, Maple Leaf Foods is making big strides toward its goal of becoming the world’s most sustainable protein provider and helping to transform food production for the better for generations to come.

Maple Leaf Foods believes that with Hitachi’s help, digital transformation can lead to big improvements in food quality, productivity and animal health. As Maple Leaf Foods continues to “Raise the Good in Food,” Hitachi is also Powering Good in the world by helping Maple Leaf Foods reach its sustainability goals.

Learn more about how Hitachi is Powering Good.

Release Date: March 2020

Solutions By: Hitachi Vantara