The Indian economic scene witnessed unprecedented growth in the manufacturing sector until the COVID-19 global pandemic temporarily halted the growth. From eight-year record high of 55.3 Manufacturing PMI (Purchasing Manager’s Index) in January 2020(1), the growth nosedived to a record low of 27.4 in April 2020(2) owing to widespread business closures. The resurgent pandemic has laid bare uncertainties in all aspects of business - production, demand, logistics, and manpower availability.

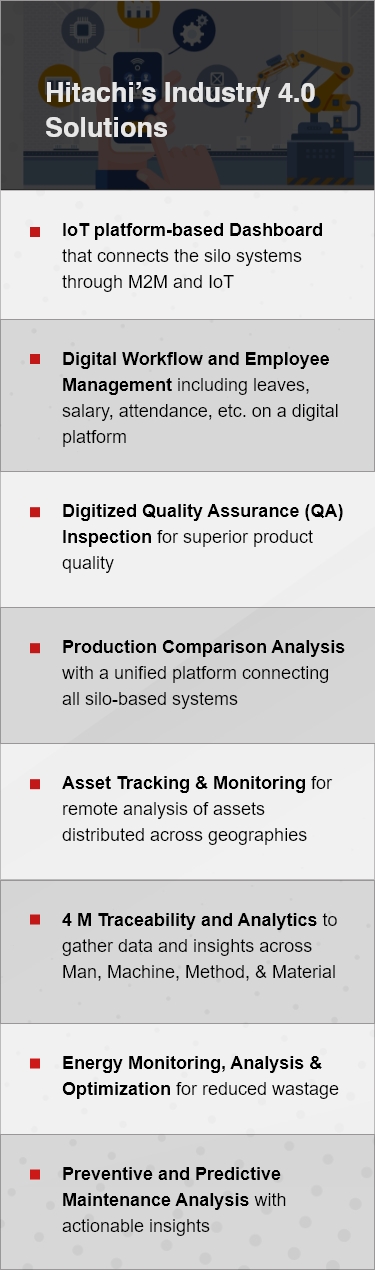

The acceleration of fourth Industrial Revolution - Industry 4.0 or Connected Factory – however holds the power to steer the industry out of the current crisis. Breakthrough technologies like Artificial Intelligence (AI), Machine-to-Machine Learning (M2M), Internet of Things (IoT), sensors, and advanced analytics can equip manufacturers with the tools and foresight they need to thrive in the post COVID-19 world.

Hitachi, which has been at the forefront of digital transformation with 100+ years of experience and legacy, firmly supports manufacturers in recovering swiftly from the crisis and evolve into agile, smart factories capable of withstanding all challenges borne out of any crisis.

⦁ Social Distancing adherence

⦁ Employee's temperature & health Monitoring

⦁ Working ambiance (temperature & humidity) maintenance

⦁ Employee location tracking & evacuation management

⦁ Online review meetings to avoid gathering at one place

⦁ Decentralized big-data based IIoT & analytics for swift decision making

⦁ Employees’ training from respective cubicles

⦁ Paperless-based SOP adherence to avoid face-to-face meetings

⦁ Digital practices to avoid face-to-face interaction & improving productivity

New technologies have always proven to catalyse new investors, spur demand and jobs, and bring greater visibility into supply chain. Industry 4.0 thus equips the Indian industry to fortify its supply chains, improve productivity, streamline operations, and acquire a bigger share of the global market.

India’s digital advancements, economic strength and demographic advantage place India in a commanding position to emerge from the crisis stronger as a Manufacturing Powerhouse. Meanwhile, the Government of India’s Rs 20 lakh crore stimulus package(3) (equivalent to $266 billion) seeks to strengthen Atmanirbhar Bharat Abhiyan or Self-reliant India Mission and revive the economy, including the manufacturing sector.

Leveraging its decades of OT x IT expertise, Hitachi is helping manufacturers quickly come to pace with the global trend of automation in manufacturing and thrive in the emerging world order.

Hitachi India Pvt. Ltd., Information & Communication Technology Systems Division, and Digital Solutions & Services Group, are assisting manufacturers identify and implement the most cost-effective digital solutions in their manufacturing operations and transform factories of past into the Smart Factories of future. Being an active collaborator and supporter of Make in India initiative, Hitachi supports and employs local talents and products to boost its manufacturing capabilities.

The complete shutdown of manufacturing operations in the initial stages of lockdown paralyzed the industrial growth impacting the livelihood of millions.

As the manufacturing sector unlocks, companies seek to ensure a safe and healthy working environment for employees, comply with government-issued Standard Operating Procedure (SOP) and actively collaborate with the government to fuel economic and industrial growth. Digital processes, automated operations, and Industry 4.0 solutions assist the manufacturers in addressing all these challenges.

Determined in its efforts to empower the industry in its fight against Covid-19, Hitachi has developed an IoT-based Tracking Solution for Contactless Scanning of Body Temperature and Face Mask Recognition.

Committed to improve the lives and safety of people, Hitachi through its Social Innovation Business solutions has also harnessed technology to innovate an IoT-based Tracking Solution for Workers Safety and Efficiency Monitoring.

In an endeavour to ensure a safe working environment for all, its imperative manufacturers adopt digital practices like digital Standard Operating Processes or Procedures (SOP), online training, digital workflow and online employee management, thereby removing the need for physical gathering and potential virus spread.

The new normal warrants greater visibility into supply chain for optimized production. The connectivity brought by Industry 4.0 via sensors, robotics, AI, and cloud computing heralds the arrival of Supply Chain 4.0 where companies can create networks anywhere, automate everything, analyze the data in real-time, and optimize their inventory and production schedules accordingly.

Automation and the emergence of cobots (collaboration between robots and humans) can address the issue of labour shortage & efficient asset utilization with companies assigning menial tasks to robots while the workers perform higher-value tasks. Further, with Industry 4.0 connecting every machine with sensors, companies can easily transition from preventive to predictive maintenance and avoid disruptions due to faulty machines.

Data analytics will enable intelligent decision making and accurate demand forecast. Optimized manufacturing processes enabled by Industry 4.0 technologies will eventually result in unmatched product quality, enhanced customer experience, and uninterrupted revenues even in times of crisis.

Hitachi is spearheading the digital industrial transformation to co-create a future of work that enhances the social, economic, and environmental values of the nation.

India shows promising potential to transform into a Smart Manufacturing Hub and position itself as a leader in the global ecosystem. There is a critical need for adopting Industry 4.0 technologies to ensure undeterred economic success and a safe working environment.

Hitachi is Powering Good using its Social Innovation Business model to help the manufacturers address critical challenges brought by the COVID-19 pandemic, promise safe working environments that enhance the Quality of Life, and support the Sustainable Development Goals of Good Health & Well-Being, Decent Work & Economic Growth, and sustainable Industry, Innovation & Infrastructure.

1. https://www.bloombergquint.com/economy-finance/indias-manufacturing-sector-activity-hits-near-8-year-high-in-january

2. https://www.livemint.com/news/india/india-s-manufacturing-pmi-contracts-sharply-in-may-11590989136124.html

3. https://qz.com/india/1856488/details-of-modis-coronavirus-package-atmanirbhar-bharat/