From the first earth day in 1970, Carbon Dioxide in the atmosphere has risen 24 percent1 emerging as the one of the primary Green House Gas polluting earth's atmosphere. It dwells in the environment for centuries and the impact borne by many future generations.

Thus, countries around the world have agreed to limit the warning to well below 2*C above pre-industrial temperatures. 2

This ambitious target can only be achieved by lowering the world's carbon footprint - a term for global warming potential that refers to the total greenhouse gas emissions associated with a product or service. Emissions of different individual greenhouses gases are converted into global warming potential and expressed in the common unit of CO2- equivalents.

As a responsible corporate citizen, Hitachi with significant global footprint formulated its long-term environmental target of reducing carbon emissions by 80% across the company's value chain by 2050. 3

Tata Hitachi Construction Machinery Company Private Limited (THCM), one of the leading constructions and mining machinery manufacturers in India realized that as an outcome of the escalating production, the CO2 footprint of its Dharwad plant may increase by a whopping 150% by 2022 of which the 77% of the estimated Carbon generated would be from Power Consumption. 3

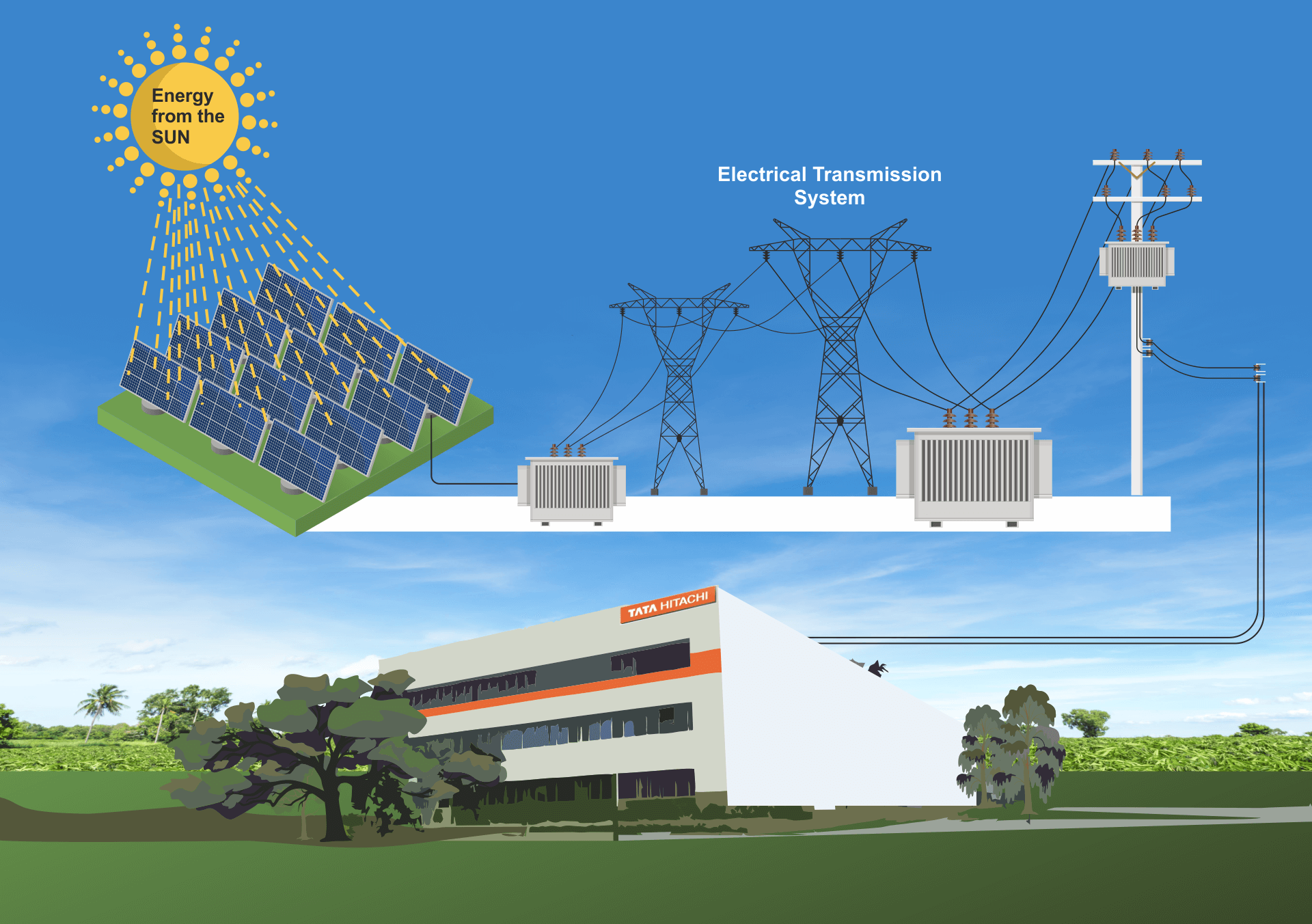

The principle reason being that a major part of the power supplied to the facility was generated through traditional fossil fuels that emit significant carbon dioxide and pollutants in the atmosphere.

The leadership strived to reduce CO2 footprint of Tata Hitachi Construction Machinery Dharwad plant by using renewable energy solutions like Sun, a very viable and reliable resource considering over 300 sunny days in the country.4

As a unique example of Collaborative creation, the team from different departments of Tata Hitachi at different locations worked together to use renewable energy solutions like solar power for power requirements of Dharwad plant from March-2018 ensuring that every product made in the factory emits less greenhouse gases compared to the previous years.

The plant opted for open access that enabled Hitachi to buy clean energy from the open market at competitive rates. Moreover, open access helped to make the investment cost almost zero and use the renewable energy as per the agreement wherein yearly consumption is forecast based on the consumption pattern and production volume.

Always on the forefront of innovation, Tata Hitachi Construction Machinery facility at Dharwad has emerged as an inspiration to avail solar power through open access in Hubli Electricity Supply Company Limited HESCOM.

The results have been beyond expectations and a benchmark for others to follow as with the introduction of solar power carbon emission due to power consumption has been reduced by 74% by replacing the depleting and polluting fossil fuel energy resources. 4

Hence, the Carbon Foot print of Dharwad plant is reduced from 1.74 to 0.8 ton CO2 per product and the facility achieved a power bill saving of 13 Lakhs (average value) per month that amounted to approximately 30% reduction in power expenses. 4, 5

Success of the Project

-

74%Reduced the carbon emission due to power consumption by 74%.

-

0.8

TonsThe carbon emission was reduced from 1.74 to 0.8 Tons of CO2 per product. -

23%Power cost reduced by 23% with the use of renewable energy.

This is only the beginning for Tata Hitachi Construction Machinery anticipates far more reduction in the future. Collaborative co-creation in the use of green solar power in manufacturing is causing a ripple effect and contributing to make the world healthier and cleaner for the present and future generations.

Source:

1 - http://medialibrary.climatecentral.org/resources/earth-day-2017

2 - https://www.reuters.com/article/us-climate-change-un/

global-temperatures-on-track-for-3-5-degree-rise-by-2100-u-n-idUSKCN1NY186

3 - https://mumbaimirror.indiatimes.com/opinion/columnists/ajit-ranade/300-days-of-sunshine/articleshow/30013611.cms

4 - TATA Hitachi Reliable Solution PDF

5 - H(I)L Screening Sheet