To build an intelligent fleet management system, Digital transformation isn’t optional — it’s a requirement for long-term success. Staying competitive in the transportation industry while delivering better business outcomes will take a forward-looking strategy. It’s time to go digital now, so you’re ready for new technologies that are on the horizon. Data analytics and solutions such as predictive maintenance and guided repair are the foundation on which you’ll build the next wave of integrated fleet management solutions, including electrification and autonomous vehicles. Building on your company’s data analytics capabilities will be essential to mitigating challenges and making the most of newer technologies now and into the future — for the good of all.

The next wave of transportation technology, including advances in battery technology, autonomous vehicles and the internet of things (IoT), will change the fundamentals of fleet management. This will bring new opportunities as well as new challenges. Electric vehicles (EVs) will help reduce carbon emissions, helping to improve the environment. But getting a fleet of EVs on the road isn’t easy. EVs can be recharged only in specific locations, with power often provided from a single local energy provider. Additionally, it takes much longer to charge an EV than to refuel a diesel-powered vehicle.

For example, even with ultra-fast Level 5 charging, which is the fastest charging level currently available, conventional gasoline refueling is much faster. Gasoline pumps in the U.S. have a rate of 10 gallons per minute, allowing most users to fill their vehicle in four to six minutes. Level 5 charging takes 12 minutes to fully recharge a 75–kilowatt-hour (kWh) battery. As batteries become larger, moving toward 100-150 kWh, their charging times will be even longer. i Recharging, like refueling, will need to be part of your transportation plan. Where are the stations along your fleet’s routes? How much time do you have to get there, and what’s the best route? Recharging becomes a logistical question — a question that data intelligence and analytics can help answer.

The rise of autonomous vehicles is also likely to create a new set of significant logistical issues. Today, driver feedback initiates most fleet repairs. If a truck sounds strange or handles oddly, the driver notices the issue and take steps to address it. With autonomous vehicles, that human input is lost. Even fuel planning needs to be handled differently because there’s no driver to refuel the vehicle.

Technological advances are already supplying the data analytics for predictive maintenance that are addressing many of these issues. For example, with connected vehicles, data is analyzed in real time so that routes can be planned and adjusted to be fuel efficient. Charging or fueling stations can also be mapped out as part of the route to best meet delivery schedules. As technology races forward, transportation companies must be ready to pivot quickly as new issues arise and new solutions become available.

The evolution in fleet management will affect not only processes but the people responsible for operating those fleets. This next wave of fleet management solutions introduces new technology that employees must understand and use. Human capital is a limited resource, and organizations need an intelligent strategy to navigate these transitions. To attract and retain workers, it’s critical to give employees an opportunity to focus on the areas in which they have interest and expertise while minimizing the time they spend on related but less rewarding activities.

As in all industrial revolutions, new advances in technology are decreasing the need for humans to perform routine tasks. At the same time, these advances are increasing the amount of work in other areas, from planning and logistics to tracking, tracing and maintenance. Electrification and autonomy do not eliminate work; they change it. This means that organizations will need people with new kinds of expertise and operational skills. Even with increased automation and predictive analytics, certain tasks such as fleet maintenance and repair will not disappear. With the right approach, organizations can apply the benefits of artificial intelligence (AI) to their fleet management systems — and free up employees to focus on what they do best, or even take on new tasks that are more strategic.

An example from public transit demonstrates how advanced analytics — and the right partner — can open up new opportunities. Hitachi recently partnered with the Intercity Express Programme (IEP) in the United Kingdom, which is in the process of replacing all of the 40-year-old trains that run on its East Coast Main Line and Great Western Main Line. ii The IEP organization turned to Hitachi Rail Europe to provide all the next-generation electric and bi-mode trains for these major routes. iii

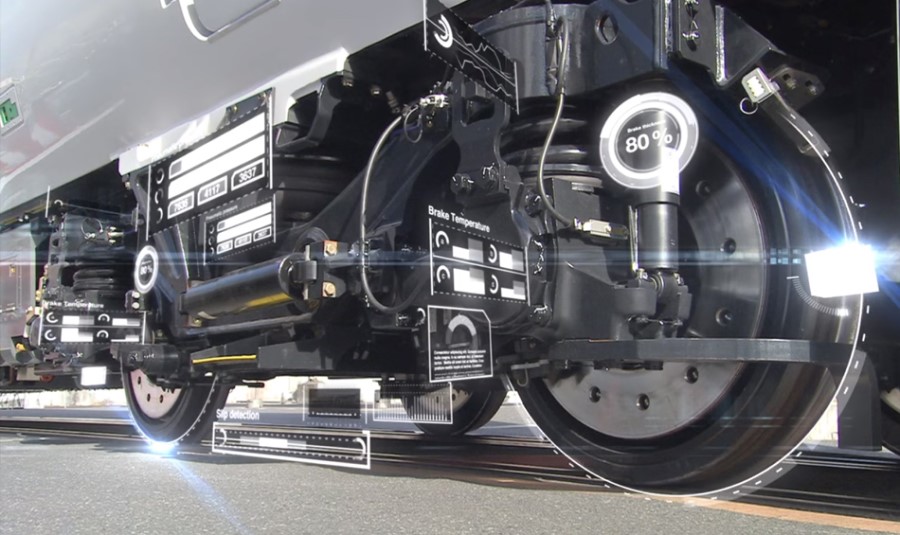

The solution was not a traditional rail model, but transport as a service. Hitachi owns, manages and maintains the trains and supporting infrastructure. Instead of incurring capital expenses, IEP pays based on agreed levels of service. In this model, Hitachi must ensure that the trains are running reliably and on time to earn revenue. A comprehensive nose-to-tail set of sensors captures data about rider behaviors, emissions, equipment condition and more, in real time at over 100 mph. Hitachi actively manages and analyzes the huge volumes of data generated by these sensors, providing valuable insights to help improve multiple aspects of IEP’s services including rider safety, train and equipment maintenance and operations, and better fuel efficiency.

For IEP to be successful, Hitachi needed to transform the way it approached train maintenance. The solution required a combination of big data technologies, predictive analytics, and condition-based maintenance to enable Hitachi Rail operations to successfully deliver optimized maintenance. This 30-year program represents a $30 billion investment for Hitachi, and with advanced data analytics and optimized, intelligent maintenance, the company is confident that the initiative will be profitable.

How can your organization begin to move in this direction? Based on our experience with data analytics for fleet management, we’ve identified five focus areas:

Start by doing some enterprise soul-searching. What data do you need to collect, how will you collect it, and how will you scale? How will you distinguish good data from bad data? You can look to other companies for examples and best practices, but the truth is that until you do it in your own organization, with your own differentiators, you won’t know how it works for you. That’s why you need to focus on getting the right insights from analytics for your business. This could mean identifying the remaining useful life of each asset in your fleet, implementing predictive maintenance to increase that life span, or ensuring that root cause analysis is part of guided repair.

Think about what will make an impact on your business not just now, but into the future. There’s a lot of cool new technology out there, but does it actually solve any of your problems? Does it have a positive effect on your P&L? Does it support your organization’s values for economic, social and environmental benefit? What does it enable? And — a question that is often overlooked — what new revenue growth opportunities will these new insights produce? As you develop your strategy, you’ll be able to align your business imperatives with your technology to fully integrate analytics with specific operations, improving performance and directly impacting your bottom line.

Creating a forward-looking strategy that moves from a reactive model to a proactive model will inevitably create change across your company. For example, you’ll probably change the way you manage your fleet or adjust the way maintenance is done. Traditionally, for instance, a technician will make the rounds every day, find what’s broken and fix it — a reactive approach. With predictive data analytics for fleet maintenance and repair, your approach becomes proactive. Predictive maintenance delivers insights about fleet repairs and health to your technicians. The technicians need to determine why they are getting a prediction, how to validate it, and how to proceed. This shifts the knowledge base and gives your business the agility you need to move quickly when requirements or conditions change.

Many industries are experiencing worker shortages as large numbers of workers retire. At the same time, new technologies such as EVs are becoming very popular, especially with fleets — but the maintenance workforce for these technologies doesn’t yet exist. The solution to this looming skills gap is leveraging data analytics for predictive maintenance. When combined with AI and augmented/virtual reality, the right data can enable technicians to use guided repair to work with confidence even on technologies they are not familiar with. Plan to recruit and hire for the next generation, and give your current workers the opportunity to apply their skills in new ways and gain new proficiencies.

Taking advantage of the data analytics boom requires a lot of data management and expertise. You’re in the fleet business, not the IT business. How will you run your operations day to day in this new, data-driven world, without creating a whole new IT department to keep the insights coming? Many organizations have turned to third-party partners to manage the IT. The best partner is one that understands your business down to the level of processes and operations, but that is also an experienced IT organization. With the right partner, your day to day operations will run smoothly, and you’ll have the data structure in place to take advantage of new opportunities as they arise.

Whatever the vehicles — planes, trains, trucks, buses, boats, or any other mode of transportation — fleets are an integral part of most people’s lives. As the transportation industry becomes more efficient, we will all experience the benefits in many ways. For example, better and more accurate deliveries affect the supply chain, both upstream and downstream, in positive ways. And when public transportation is cleaner, safer, and more reliable, everyone wins.

Building smarter, more efficient fleet management isn’t all about dollars and cents — it’s also about powering good. A successful data analytics solution will also have a positive net effect on the environment and society. Fleets are more efficient when they are maintained at their peak operating level, so deploying a well-designed analytics solution can deliver a significant impact through reduced waste, lower carbon emissions and other environmental benefits.

At Hitachi, we are committed to powering good by driving social, economic and environmental benefits across all of our engagements. By co-creating solutions with businesses and communities around the world, we bring together the best minds to power smart cities, sustainable solutions and a better quality of life for all.

Although broad implementation of EVs is currently five to seven years away, and that of autonomous vehicles is a bit further out, the pace of change in the transportation industry is accelerating. According to Neuberger Berman, revenues from next-generation mobility technology will experience a compound annual growth rate (CAGR) of 21% between 2017 and 2030.iv Fleet management organizations will need to act fast to adopt advanced analytics today if they want to remain relevant tomorrow.

Hitachi can help accelerate your road map to a robust future. In addition to IT consulting services, we also bring industry expertise. Hitachi owns and operates approx. 800 group companies worldwide, and we have deployed and proven our technology throughout our own organization. We have the industry and technical knowledge and experience to help your organization meet the future.

If you’d like to learn more about how Hitachi can help you get on the right track for tomorrow’s fleet management, click here.