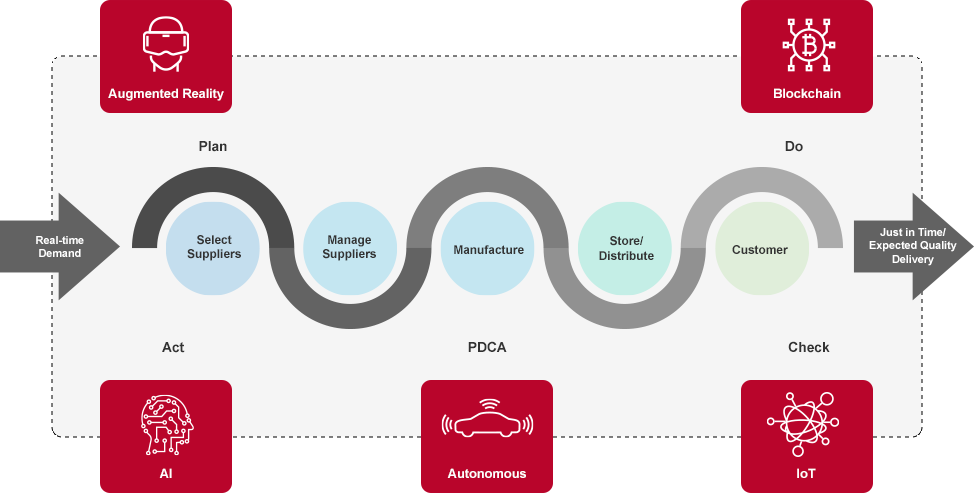

Supply Chain 4.0 is described as a “plan, do, check and act” model in which the planning cycles are digitally linked and based on a 360-degree view of the supply chain. Individual and overall feedback loops contribute to continuous and simultaneous communication. In today’s digital age, Supply Chain 4.0 represents a major shift in the way companies operate, gain a competitive edge, and become leaders in their respective industries.

In the early 21st century, the movie rental industry was dominated by a single, multibillion-dollar company with millions of customers and thousands of retail locations. In 2000, Reed Hastings, the CEO of Netflix, was laughed at when he approached the CEO of that video rental company for a partnership. In 2023, around 9 million subscribers joined Netflix around the globe in the third quarter, surpassing Wall Street analysts' forecast for 6 million1, while the video rental company is no longer in existence. As for its growth, Netflix leveraged advanced digital technologies such as big data , artificial intelligence (AI) and machine learning(ML) to train the system2, and customize the content for its varied customer base.

Like Netflix, several corporations have used disputative technologies to eliminate competition and capture market share, Tesla by-passed third-party dealerships and disrupted the automotive service model by providing updates directly to the consumer via their over-the-air (OTA) software updates for their electric vehicles4. Adobe, Microsoft and other providers are have moved away from products like storage and software to provide public cloud platforms and services like Amazon Web Services (AWS), Microsoft Azure and others5.

The traditional supply chain can be described as a linear “plan and control” model that is characterized by multiple, siloed and disjointed planning cycles, each with only a partial view of the supply chain leading to ineffective feedback loops, communication and collaboration that can lead to excessive firefighting. Compounding factors are an increased variation between suppliers, an imbalance between supply and actual demand, and increased inventory. The combination of these factors can lead to ineffective responses, failures in on-time delivery (OTD), diminished quality and efficiency and increased costs and resources. The overall result is an inability to achieve operational excellence.

In a predictable and consistent business environment, this model is very functional — and has served many organizations well for decades. In the current digital and disruptive environment, it is apparent that the traditional supply chain model is not a good fit and a new model must be adapted.

Supply Chain 4.0 is an upgraded supply chain model of the future needed for overcoming the four disruptive forces, and for achieving business success in the age of Industry 4.0. Companies like Hitachi are providing cutting-edge solutions to clients to overcome these disruptions and establish supply chain 4.0 solutions for optimal results.

Supply Chain 4.0 represents the next evolutionary stage in supply chain management. It is characterized by the seamless integration of advanced digital technologies, including IoT, AI & ML, data analytics and automation. This digitized supply chain enhances real-time visibility and enables more agile, data-driven decision making. Supply Chain 4.0 is your path to achieving operational excellence.