By Jeff Winter, Sr. Director of Industry Strategy, Manufacturing Hitachi Solutions Americas

In 2011, Professor Wolfgang Wahlster, the director and CEO of the German Research Center for Artificial Intelligence, outlined a concept he described as “Industry 4.0".1

Industry 4.0 was not just about optimizing production lines; it was a holistic transformation that would impact every corner of a manufacturing operation with production, management, supply chain, and customer service communicating seamlessly through the language of data and analytics. Despite varying interpretations of Industry 4.0, the term nonetheless became a shorthand term to describe a fourth industrial revolution marked by the process of digital transformation.

Since then, Wahlster’s vision has come into fuller view with the emergence of retrofitted "smart factories" deploying a myriad of new digital technologies, such as sensors, IoT devices, and digital twins. And thanks to the rising use of Artificial Intelligence (AI) – particularly Generative AI (GenAI) - that evolution is accelerating, moving the world closer to a second wave of digital manufacturing.

But let’s also recognize that AI can’t be bolted on as an attachment. It needs to be integrated into an organization’s planning process to affect the desired process gains.

Discussions about GenAI's capabilities started with the introduction of Generative Pre-trained Transformer 2 (GPT-2) in 2019, but its full promise only became palpable to businesses later. Between late 2022 and early 2023, the emergence of consumer-facing GenAI tools marked a significant shift in how the public and the business world perceive AI's potential. Thanks to GenAI, it has since become more valuable, more cost effective and more enhanced as a capability.

GenAI is a subfield of AI that focuses on creating new content, data, or solutions autonomously by learning from existing data. It leverages machine learning techniques, particularly deep learning and neural networks, to generate outputs that resemble real-world examples. This technology has a wide range of applications, enabling more creative and diverse solutions across various domains. Popular GenAI models include Generative Adversarial Networks, Variational Autoencoders, and Transformer-based language models (e.g., ChatGPT).

In their rush to jump on the AI bandwagon, many manufacturers press ahead without having metrics to grade their success or measure their return on investment. Perhaps that approach is driven by a desire not to get left behind and to “do something.” Whatever the reason, it’s a mistake that leads them to spend money without fully understanding what they’re doing.

Customers are understandably eager to know what their strategy ought to be. When asked, my response is that I don't really think that it’s necessary whether they have an AI strategy or not. But I want to learn about their business strategy, which should have AI as a component.

Consider this analogy. Clearly, it's critical for businesses to use electricity, but not every company has an electricity strategy per se. Similarly, you don't need an AI strategy. AI is just a tool. So, you can have a business strategy that uses AI in the same way that electricity gets used in every aspect of what a business does.

Bottom line: having an AI strategy by itself might not work. Instead, you need to be thinking about AI as a tool. It's a cool, very capable, all-purpose tool. But it needs to be thought of as a tool.

As AI wends its way throughout the business world, it’s also helping manufacturers make more informed decisions. Consider the following:

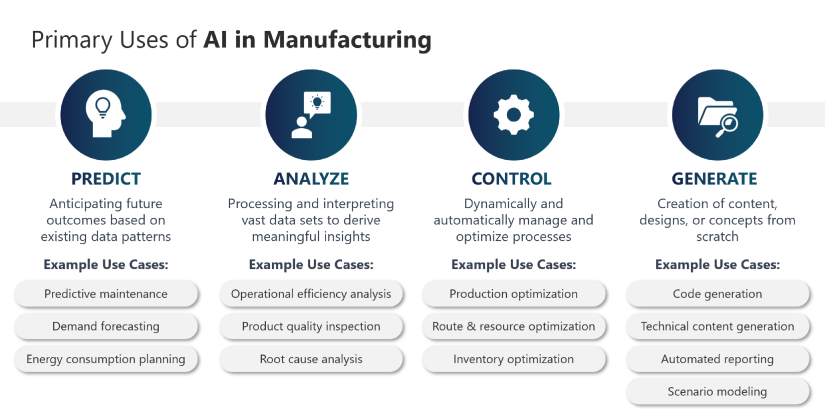

Prediction: AI helps to anticipate future outcomes based on existing data patterns. Demand forecasting, supply chain and predictive maintenance are two of the hottest use cases right now for different functions within the manufacturing industry.

Analysis: Manufacturers can use AI to sift through massive amounts of data and make sense of it to find patterns, correlations, connections, and anomalies, many of which previously escaped notice because they were too subtle or too complex. Your analysis can then feed back into your predictive models to drive decision making.

Control: Prediction and analysis help augment human decisions by equipping them with better information. When it comes to Control, we’re talking about letting AI take the wheel and make decisions for the company. For example, PepsiCo successfully deployed an AI development toolkit to raise quality control in their production of Cheetos snack food. The quality of individual Cheetos depends upon different input factors, such as humidity or the moisture of the corn meal. Until now, company employees had to constantly adjust knobs on the extruders to ensure top quality production. No longer. They were able to create a model of the physical extruder and then trained an AI agent to autonomously supervise the settings on the machine to create the perfect Cheetos.2

Generation: AI does more than number crunching. It's also a powerful tool for creativity with the proliferation of assistant systems, recommendation systems and autonomous systems which leverage generative AI to guide decision making.

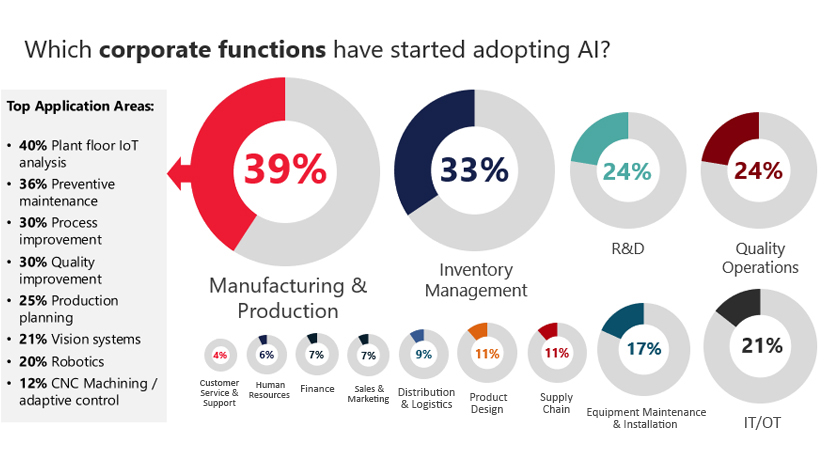

Research by Capgemini, a French multinational information technology services and consulting company, shows an increasing trend of AI uses in the manufacturing sector globally, where nearly 29% of use cases are observed in maintenance and 27% in quality3. New applications for GenAI are being written all the time, particularly for frontline employees working for manufacturing organizations. It runs the gamut from field service technicians writing up reports to maintenance technicians to operators who need to enter in data about what happened during the daily production run.

Source: The Future Of Industrial AI in Manufacturing, The Manufacturing Leadership Council

https://www.manufacturingleadershipcouncil.com/wp-content/uploads/2023/06/The-Future-Of-AI-In-Manufacturing-MLC-2023.pdf

In other words, this is fast becoming a must-have capability. But getting to the finishing line is hard. Even before GenAI emerged, customers faced challenges navigating past the shoals to successfully complete digital transformation projects. The advent of AI makes it that much more complicated.

The senior executives who sign off on spending decisions inside businesses don’t have the deep technical understanding necessary to vet technologies for big transformational projects. That’s understandable. None of this is trivial and operational gurus around manufacturing processes are rarely also AI experts. They’re not engineers and they don’t know how this works or how it’s supposed to fit together. But as companies think about how they’re going to compete in this nascent industrial revolution, this isn’t something where they have the luxury of getting it wrong.

Indeed, digital transformation is still increasing at an accelerated rate. In a recent survey of 185 CFOs, Gartner said that respondents named digital transformation as their top focus for 20244. The incorporation of GenAI only adds a further challenge to overcome.

In an increasingly autonomous future, AI integration has become too strategic to leave it on the back burner. Here’s where an experienced strategic partner can help clients ensure that these various technologies come together successfully. Hitachi understands how the pieces fit and has been helping clients with their digital transformation projects for the last decade.

Talk to an expert today.

Sr. Director of Industry Strategy, Manufacturing, Hitachi Solutions Americas

Jeff Winter is the Sr. Director of Industry Strategy for manufacturing with Hitachi Solutions. With over 18 years of experience working for different industrial automation product and solution providers, Jeff has a unique ability to simplify and communicate complex concepts to a wide range of audiences, educating and inspiring people from the shop floor up to the executive board room. As part of his experience, Jeff is also very active in the community of Industry 4.0. He currently is a part of the International Board of Directors for MESA (Manufacturing Enterprise Solutions Association), the leader of the Smart Manufacturing & IIoT Division of ISA (International Society of Automation), a U.S. registered expert for IEC (International Electrotechnical Commission) as a member of TC 65, and is on the Smart Manufacturing Advisory Board for Purdue University