As COVID-19 spreads, remote work is becoming part of the "new normal." Going forward, companies are expected to increasingly adopt a hybrid style of working that balances remote and non-remote work.

It is not just office workers that are experiencing such change. A movement has also started in the manufacturing industry to introduce remote work into the front lines of production.

Garnering expectations in these times is "Smart Factory as a Service," a service that enables the remote management of factories anywhere in the world.

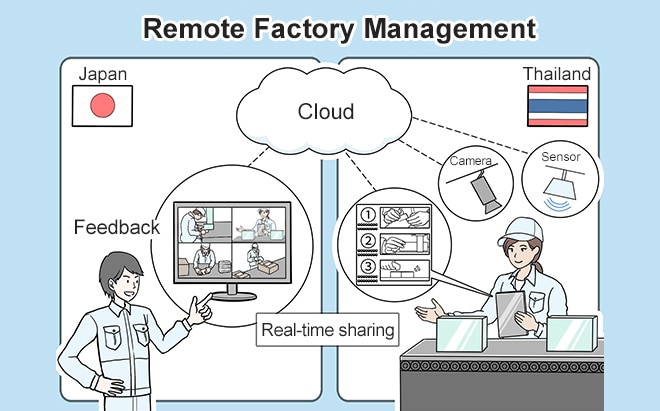

Overview of remote factory management

“Smart Factory as a Service” enables companies to grasp the internal situation of overseas factories through cameras, RFIDs (electronic tags), and various sensors which are installed at the work site. Such data is then shared via the cloud and kept track of by managers and technicians at parent factories in Japan in virtually real time. Multiple cameras are installed, enabling the ascertainment of detailed information about the production line, thus serving not only in keeping track of the state of operations but also in investigating the causes of unexpected problems.

The ability to share factory infrastructure among multiple enterprises is also a tremendous advantage. Normally, when a production base is placed overseas, a large amount of labor and funds are required for such tasks as local market surveys, factory construction, materials procurement, and staffing and training.

In this respect, because sharing factory infrastructure makes it possible to avoid large-scale facilities investment, small and medium-sized enterprises (SME) in the manufacturing industry are particularly in a position to enjoy considerable advantages from “Smart Factory as a Service”. In addition, trading company functions such as logistics and sales are also available for use, making it possible to minimize the needful resources and potential risks for overseas expansion.

Small and medium-sized enterprises now also face the need for international expansion (Photo: Getty Images)

Mr. Yo Nakajima of Hitachi High-Tech Corporation conceived of "Smart Factory as a Service" in 2017, when remote work was starting to spread among a start-up company in Japan. This idea was triggered by a sense of mission that translated into a desire to support the overseas expansion of Japan's SMEs.

In recent years, the manufacturing industry has seen an increase in manufacturers maintaining overseas manufacturing bases, giving rise to an accelerating movement toward the local sourcing of components and materials. As a result, SMEs that are providers of components and materials are being called on to expand internationally. However, for companies in the midst of an increasingly severe management environment, funding and human resource aspects are a considerable barrier.

Having witnessed such a severe situation firsthand and believing that a system was needed for assisting SMEs in their overseas expansion by using the remote management of factories and the sharing of production facilities, Mr. Nakajima formed a project team in January 2017. Participating in this team are six companies that resonated with his ambition to invigorate Japan's MONOZUKURI (making things) . Joined by companies with expertise in video processing and cloud-based information processing, the team has successfully gathered the technologies required to realize the project.

Looking back on his state of mind at the time, Mr. Tomonori Haba of CRI Middleware Co., Ltd., one of the project participants, says that "I had this idea of making use of our technology at the corporate level and for the manufacturing B2B sector, so I was quite excited because our image compression technology was showing promise in being able to support Japan's MONOZUKURI."

Mr. Shigeo Ishihara of INES Corporation says that "I had a desire to participate in open innovation and take on a new challenge. I felt that we could apply our technologies for internet and cloud infrastructure to new industrial fields and uses."

This project team, formed by members from different fields, and having received support from the Japan External Trade Organization (JETRO), began Proof of Concept in Thailand in October 2017.

At work during Proof of Concept in Thailand

In the Proof of Concept that began at Thailand, it was decided to carry out the manufacture of elevator handles and control devices remotely from Japan. But, right from the start, the project team ran into a major problem. It was discovered that when trying to communicate elevator component work procedures to Thai workers, it was impossible to successfully convey Japan's artisan-type skills. The know-how for making products of the same quality as Japan had not been documented anywhere—it existed only in the minds of veteran artisan workers.

In order to conduct manufacturing remotely, Japan's bases needed to share with local factories the prerequisite knowledge and detailed work procedures related to MONOZUKURI. Interviews were carried out on artisans’ processes in Japan, and procedural manuals were created in Japanese, English, and Thai. Mr. Tetsuya Hasegawa of Hitachi Industry & Control Solutions, Ltd., who oversaw manual development, recalled that "visualizing the know-how drawn out of craftsmen in a form conveyable to anyone was challenging."

Moreover, in order to make minutely detailed instructions possible, the company developed "digital recipe," an image-based work instruction manual. The movements of Thai workers are recorded using sensors, which are then checked if they meet the standardized work acceptance criteria. This process makes it possible to come to an immediate judgement as to whether or not quality standards are met at each work process and to provide instant feedback to workers. Spelling out specifications that require standards to be cleared before progressing to the next step made it possible to accomplish each task successfully.

Digital recipe created for Thai workers

It was also soon realized that it was crucial to compress as much as possible the high-quality image data captured by nearly 100 cameras. Here, CRI Middleware's game industry-leading video compression technology played a critical role. According to Mr. Haba, "In order to accurately convey what's going on at the work site, it was necessary to get maximum performance for elements that previously had a trade-off relationship: level of compression versus image resolution. I believe that what made it possible to significantly compress video data volume while maintaining quality was our technology cultivated through the video compression of over 5,000 game software products."

After the Proof of Concept in Thai, “Smart Factory as a Service” was commercialized in April 2020 as a service called “CHIPS”, a video-based visualization service. A movement toward using CHIPS has already sprung up within the Hitachi Group.

As a measure for preventing COVID-19 infections, Hitachi High-Tech Fine Systems Corporation, a producer of railway-related products and industrial automation facilities, has limited people traffic inside factories and reduced the number of staff on its manufacturing lines, in order to avoid the 3Cs (closed spaces with poor ventilation, crowded areas, and close-contact settings).

CHIPS was then introduced to enable managers to keep track of operational statuses remotely. Although CHIPS is currently being used in the management of work processes in Japan, the company has plans to expand its scope of use in the future. As Mr. Hideki Yonezawa of Hitachi High-Tech Fine Systems enthuses: "I'd like to actively make use of CHIPS in the deployment of overseas production in the near future."

Hitachi High-Tech Fine Systems' Saitama factory which recently introduced CHIPS

Mr. Yonezawa goes on to say that "Most craftsmen-like workers at the work site have a 'watch and learn' mindset. Because you can learn by repeatedly watching a video, I feel that a smart factory work instruction manual represents a landmark with respect to the passing on of know-how in the manufacturing industry to future generations."

Although “Smart Factory as a Service” came about as a means to support the overseas expansion of SMEs, the COVID-19 crisis has triggered expectations for its use in various other fields. As Mr. Nakajima of Hitachi High-Tech says about future prospects, "It can be applied to work environments in medical, construction, and other settings that require specialty technologies and functions."

Various industries are in the process of great change, including the way we work. In the manufacturing domain, the vulnerability of the global supply chain to unexpected events has become apparent due to the COVID-19 pandemic. In this age of unpredictability, “Smart Factory as a Service” may become a "new normal" that supports the manufacturing industry of the future.