As COVID-19 continues to spread throughout the world, many people are now working from home. At the same time, medical practitioners and others deemed “essential workers” must continue to go out to their workplace. The situation is the same for scientists and researchers at research and development departments. Because they need to use special facilities to conduct research and experiments, working from home has its limits. It then becomes a question of how to continue research activities while reducing infection risk to a minimum. In this article, we looked into initiatives being pursued at Hitachi’s Central Research Laboratory in Tokyo.

Kyōsō-no-Mori facility, located at Hitachi's Central Research Laboratory complex in Kokubunji City, Tokyo

In March 2020, while COVID-19 infections were spreading by the day, Hitachi's Central Research Laboratory faced a challenge. Although a rigorous company-wide policy of remote work had been announced, many researchers spoke up on the difficulty of continuing research without going to their labs.

The Central Research Laboratory is the site of a wide range of research and development activities with numerous experiments in progress. This includes research into biotechnology, electronics, city infrastructure, and energy, all being conducted at the Center for Technology Innovation – Electronics and Instrumentation, which is staffed by over 300 researchers. Here, experiments that rely on special equipment and specialized facilities are essential. Unless researchers are present at the center, their work cannot proceed as intended.

To address this, a work shift system was introduced at the Center for Technology Innovation – Electronics and Instrumentation in May. This system allowed research activities to be maintained by limiting the number of people coming to the center for avoiding the 3Cs (closed spaces with poor ventilation, crowded places, and close-contact settings). Speaking about his state of mind when the system was introduced, General Manager Mr. Yasuhiro Shimamoto says that "Avoiding the risk of infection is of course a given. As we are also conducting experiments requiring safety considerations at the research and development worksite, my top priority was safety.”

However, when trying to organize shifts for 300 people, Mr. Shimamoto found that manually creating optimal shifts required considerable time due to the complex relationships between all pertinent items, including teams belonged to, research contents, test progress, test equipment usage status, workplace, commuting frequency, and commuting time.

As he puzzled over how to create these shifts, one of the research teams at the center learned of his predicament. The team saw the potential of a technology that it was developing for customers in shift creation. This team was in charge of the development of an advanced computer technology known as “CMOS Annealing.”

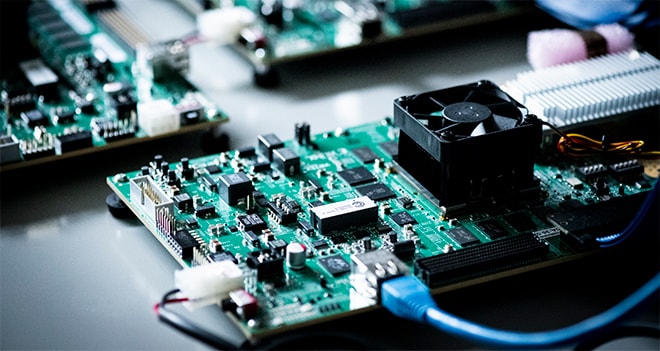

CMOS Annealing circuit board

CMOS Annealing was developed in 2015 by Hitachi. Specializing in optimization, this technology is capable of rapidly solving extremely complex calculation problems called “combinatorial optimization problems.”

One example of such a problem is route guidance for vehicles. This task requires selecting the optimum route from among a limitless number of route combinations after considering traffic information, weather, and other factors subject to moment-by-moment change. CMOS Annealing uses proprietary formulas and algorithms to find the most-efficient combination. It is expected to find application in fields previously regarded as highly problematic for optimization. These include the speedy and waste-free picking of needed articles at logistics warehouses and the creation of portfolios for financial products.

The center decided to use CMOS Annealing in the creation of work shifts that avoid the 3Cs. First, the developers worked toward sorting out requirements for the data needed for shift creation.

Because various research projects are underway at the center, the developers needed to identify factors such as work contents and number of development team members in accordance with each research project. Additional requirements, such as the need for mentors to be at work on days when new employees came in, also appeared one after another. It was a daily task to rewrite the calculation program upon the discovery of a new requirement.

It was particularly troublesome to define requirements related to COVID-19 infection risk. According to Mr. Takuya Okuyama, who was in charge of development, “The center has nearly 100 test labs ranging from small to big, and we had to verify directly at each lab its optimal number of workers. Determining the requirements lab-by-lab was arduous work.”

Having raised precision in this way, CMOS Annealing-based shift creation now makes it possible to create weekly shifts for the 300 people at the center in just about one hour. Compared to processing this by a regular computer, CMOS Annealing enables shift creation that is nearly 100 times faster. And, even if there are sudden changes in planning, the shift can immediately be rewritten.

One month after using CMOS Annealing to create shifts, there has been many feedbacks from the employees. Development teams appreciated having been able to procure time and space for experiments to be conducted while avoiding the 3Cs. Also, unexpectedly enough, they said that as long as CMOS Annealing instead of a person was creating shifts, they could accept that their preferences could not always be met.

The development team hopes that CMOS Annealing-based shift creation will be deployed throughout the Hitachi Group in the future. Says Mr. Okuyama: “I'd like to see the system improved so that anyone can implement it, thus making it possible to enjoy the advantages of CMOS Annealing even without expert knowledge.”

Yasuhiro Shimamoto, General Manager of Center for Technology Innovation – Electronics and Instrumentation

Mr. Shimamoto, manager of the center, also points out that shift creation using CMOS Annealing has the potential to play an important role in promoting new workstyles.

He goes on to say “I believe the future will witness a big shift to flexible workstyles that take advantage of the benefits of both remote work and working at office. This initiative may very well become one of the systems that supports the changing workstyles after COVID-19.”