Satoshi Okada, Ph.D., senior engineer of Hitachi-GE Nuclear Energy's Nuclear Equipment Design Dept., oversees the development of “PMORPH”, a robot used for investigating the basement floor inside the Unit 1 PCV.

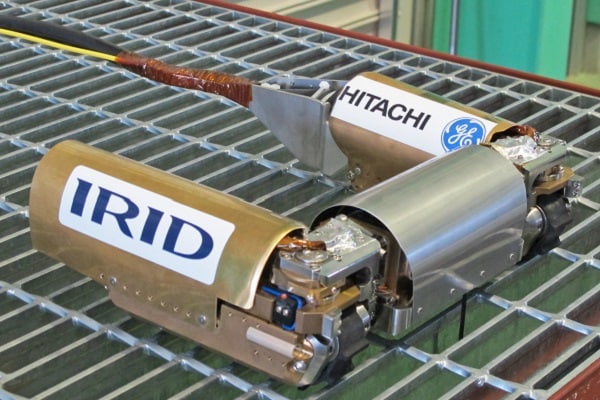

On March 18, 2017, the “PMORPH”*1 entered the disaster site of the Fukushima Daiichi Nuclear Power Station Unit 1.*2 Developed by Hitachi-GE Nuclear Energy, the “PMORPH” was designed specifically to investigate the basement floor inside the Unit 1 PCV, the site of nuclear fuel meltdown. According to the Mid-and-Long-Term Roadmap towards the Decommissioning of Tokyo Electric Power Company(TEPCO)’s Fukushima Daiichi Nuclear Power Station, an outline of the process leading to reactor decommissioning, fuel debris resulting from the meltdown is scheduled for removal from 2021. The purpose of this investigation was to lay the groundwork for considerations on removal methods. The question is: What's going on in there? The “PMORPH” investigation represents a step toward decommissioning. We talked to its developer about the ramifications of the investigation. We also asked about the issues involved regarding robot development from the perspective of decommissioning and about the current state of progress. In addition, in an unexpected discovery, it turns out that the key to a robot functioning in an environment of unprecedented severity was old-fashioned analog technology and communication among people.

*1:“PMORPH” was developed with the Subsidy Project of Decommissioning and Contaminated Water Management by Ministry of Economy, Trade and Industry (METI).

*2: For a background on the robotic investigation of the basement floor inside the unit 1 Fukushima Daiichi Nuclear Power Station's PCV, see A look inside: One step closer to nuclear plant decommissioning

The “PMORPH” development goals: “Adaptability to conditions” and “Capacity to withstand to severe environments”

Immediately following the disaster at the Fukushima Daiichi Nuclear Power Station, robots from both Japan and abroad were sent in to get information needed for disaster containment, decontamination, and decommissioning. Even before the disaster, however, robots already had a long history of development and operation in nuclear power plants, thus a considerable technological base already existed. Bringing these technologies to Hitachi's R&D group, Satoshi Okada, Ph.D., senior engineer in the Nuclear Equipment Design Department of Hitachi-GE Nuclear Energy, Ltd. and manager of the development of the “PMORPH” for investigating the PCV interior, had extensive experience prior to the disaster in the research and development of robots for use in regular inspections of nuclear power plants. As he explains:

"Before the disaster, I was in charge of the robots used to investigate the inside of water-filled facilities during regular inspections of nuclear power plants. Controlled remotely by people, these robots would go into confined and low-visibility areas to check out the state of the facility. Although this technology became the basis for this project's robot, the basic development conditions are completely different, which raised some major questions for us. Now, since water shields from radiation, despite it being the inside nuclear facilities, the effects of the radiation are actually limited. But the work to be undertaken after this disaster would have to be done in a severe environment with prospects of extreme radiation. We therefore had to start from scratch in considering what type of robot to develop."

Robots evoke the image of a machine with precision instruments that can assess situations independently, allowing them to work as efficiently as human workers or better. However, these very aims of ordinary robot development turn out to be weaknesses in the severe environment targeted in this investigation. The higher the precision of the instrument, the less it can tolerate radiation, and agility under poorly understood conditions could cause unpredictable problems. Robot development for this mission would require the rejection of conventional ideas regarding high-performance robots and the need to start fresh. Okada sheds light on this:

"If I stand there, I can't stand here. That's the dilemma. When you hit a wall like this during development, there is an approach to thinking that can suggest what next to do. We separate out the conflicting issues. If high performance is a drawback, then we don't have to make a high-performance robot. If we extend the robot’s precision instruments or other parts that are vulnerable to radiation to outside the robot’s body, then the resistant parts can remain in the robot. Executing control by remote operation, we dispersed technologies into each of these areas to overcome our issues."

The idea was to limit the integration of precision instruments on the robot to the minimum and to leave situational judgement to the operator via a cable. So, in the case of the first robot that went into the Unit 1 of Fukushima Daiichi Nuclear Power Station in April 2015, the operator himself performed positional determination analysis using data obtained from a built-in horizontal laser. The adoption of such analog technology enabled the building of a robot capable of working under severe conditions.

The strategy of starting from scratch also gave rise to the concept of a shape-changing robot. Inspired by the long, narrow pipe comprising the robot's path into the PCV and the necessity for stable travel on the grating, the developers decided that the robot should be able to change its shape in order to adapt to varying conditions. Okada continues:

"The name “PMORPH” is the combination of the first letter of PCV and the middle syllable of the word 'metamorphosis,' which refers to an insect changing its form. By raising awareness regarding this word throughout society, I hope to obtain the people’s understanding of the problems involved in investigations for decommissioning and of the robotic functions that will help us prevail over them."

An investigation of the basement floor inside the Fukushima Daiichi Nuclear Power Station's Unit 1 PCV was conducted from March 18 to March 22, 2017. The investigation was conducted by lowering a unit mounted on “PMORPH” and equipped with built-in camera and sensor into the water covering the bottom of the PCV. The purpose was to find out how the fuel debris from the meltdown had spread by measuring radiation amounts and using underwater images. (See A look inside: One step closer to nuclear plant decommissioning for more information.) In preparation for this task, the April 2015 investigation results were used to determine a course for robot travel, while a full-scale mock-up of the PCV was employed for training in precision operation. These and other preparations allowed the team to accomplish the investigation of five planned sites. In addition, the team also succeeded in recovering and collecting the “PMORPH” from the PCV. These results demonstrate the improvement of overall investigative technology utilizing a robot under severe conditions. However, according to Okada, this was also for the discovery of “new” issues. Says Okada:

"You'll forgive me for boasting if I say that, with respect to a robot adapted to its investigation objective, we scored nearly 100 out of 100 points in development, operation, and execution results. When going somewhere no one's ever been, you will encounter different situations than during simulations. In our case, for example, the water had more sediment than expected, so under current circumstances we were not be able to get a clear view of the fuel debris from the image data. We are now proceeding with analysis that will let us deduce the actual situation using data from radiation measurements. We go in there because there's much that we don't understand. Going lets us know what we don't know. The new issues involved in finding out what we don't know will guide us toward the next step in decommissioning."

There are hardly any precedents or examples to follow when it comes to developing the type of robot needed for investigating the disaster site of the Fukushima Daiichi Nuclear Power Station and for decommissioning. It is not even possible to do the testing needed to refine performance. While the successful entrance into the site served as a demonstration experiment, the actual investigation will require high-precision operation in order to yield results that will lead to the next step. To raise robot resistance to radiation, the structure settled on for the “PMORPH” integrates a minimum of precision instruments. The operator of such a robot must be extremely precise. The key in the development phase toward obtaining a sure connection between operator and robot was communication among people. According to Okada:

"We had people developing technology, people making the robot with that technology, people operating that robot, and people bringing it all together. There was no way that we could send the robot into an unknown place and achieve our purpose without these people sharing a common direction in a common arena. This was on my mind at all times. To accomplish these required conversations; the ultimate in the multiple application of analog approaches was essential. In this sense, I was impressed by how teamwork, as part of Hitachi's work culture, manifested itself in this mission."

Advances are expected in determining the state of the fuel debris based on an analysis of the results of this investigation. The removal of fuel Debris is scheduled to begin from 2021. In addition to robots for investigation, Hitachi is developing the “Flexible Structure Arm (also known as the Muscular Robot) “,*3 envisioned for such work inside the PCV as assembling simple devices and transporting and recovering cut-away fuel debris. Hitachi will continue to develop technologies aimed at the final decommissioning of the Fukushima Daiichi Nuclear Power Station.

*3:“Flexible Structure Arm (also known as the Muscular Robot)” was developed with the Subsidy Project of Decommissioning and Contaminated Water Management by Ministry of Economy, Trade and Industry (METI).

Click here to go to the IRID website for more information on the progress of the development of remote operation technologies and the “Flexible Structure Arm (also known as the Muscular Robot) ” for use in the fuel debris cleanup.

Date published: June 2017