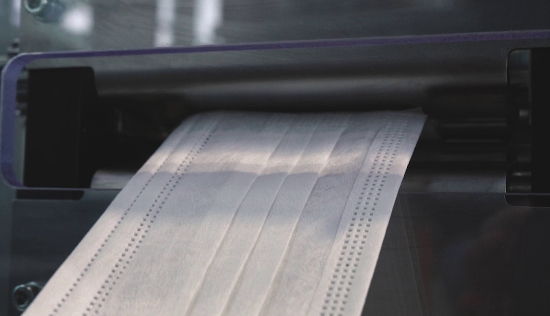

One of the most immediate and critical impacts of COVID-19 was a rapid and severe depletion of personal protective equipment (PPE) for first responders. Demonstrating their commitment to social responsibility, General Motors (GM), JR Automation, A Hitachi Group Company and Esys Automation were quick to respond to this shortage and create immediate capacity to manufacture face masks. When GM put out the call for help from employees, the response was abundant and swift. Through a combined effort between leadership, engineers and employee volunteers, the GM/Hitachi team designed an end-to-end production line, sourced and repurposed supplies, and transformed a GM cleanroom into a mask factory in a record-breaking six days. As of the end of May, this unique factory ― built from innovative thinking and personal commitment to powering good in the world ― is churning out tens of thousands of masks per day.

When COVID-19 hit the United States, the first question GM leaders asked was, “What can we do to help?” When it became clear there would be an issue with supplying the nation’s first responders with enough PPE, GM connected with Hitachi’s JR Automation to address the shortage. GM and Hitachi have a long-standing relationship when it comes to creatively solving problems and meeting GM’s needs.

“The PPE shortages were unprecedented, and the manufacturing community knew we needed to respond in some tangible way. All through the Hitachi community, we were asking how we could use the assets we have in a different way to really make a difference during this crisis,” says Bryan Jones, CEO of JR Automation. “When we heard that GM was looking for a way to help healthcare workers, we reached out.”

The connection immediately mobilized Esys and JR Automation to figure out a way to help GM produce a “mask machine” in a very short timeframe. Within hours, GM, Esys and JR Automation were in conversations about how they could have a mask manufacturing line up and running within a week’s time.

The challenges were many. While there was a potentially leverageable GM design for the type of equipment JR Automation would need to produce masks, the design schematics were all in Chinese — and there were hundreds of them. And while JR Automation had some experience in producing mask-making equipment, it was for N95 masks, not face masks.

In addition, mechanical engineers would have to make modifications to some of the drawings to ensure safety and compliance with U.S. standards. Technicians would be needed to assemble the machinery. Trained production workers would be needed to run the line. Because the design originated in China, there were no parts readily available in the U.S. and this required sourcing from many new vendors.

Complicating the process was that supply chains for PPE materials were in great demand, and many were depleted. Finally, bringing up an operating line is a commercial venture and there are many steps that must be taken at the leadership level to be successful. This can be a lengthy process.

And it all needed to happen within six days.

It began with a phone call on a Saturday evening. The joint team threw itself into an around-the-clock collaborative effort to get masks into production. Inspired by a commitment to help the country in a time of urgent crisis and fueled by expertise on all sides.

“There were a lot of things that needed to come together. Being able to pull it off within six days was one of them. But it comes back to what kinds of things you need to know to be able to do this effectively,” Jones explains. “I think that's one of the unique things about JR Automation. We have a very deep resource knowledge base across a very broad range of industries.”

Esys Automation contributed the technical capability to take a functioning design for another product and convert it for a new purpose. GM brought to the table significant materials expertise, including resources and facilities, across a broad range of industries. An important factor to GM was to ensure the team was sourcing material that was new to the marketplace, rather than adding an additional burden to the over-taxed PPE supply chain.

“There is a significant amount of technology in the materials inside a mask. The three different layers, specifically the center layer, are not easy to produce. We worked with our product engineering staff to source new material from our current automotive suppliers,” says Rob Portugaise, GM executive director of global manufacturing engineering. “GM went to bat for current suppliers to pull together everything needed to facilitate manufacturing that material and not deplete other resources around the globe.”

And so began a cadence of converting drawings from Chinese to English, modifying and releasing the drawings to build, purchasing components, and cutting parts for the machinery. As suppliers got wind of the project, they accelerated their turnaround times from weeks to hours.

By Wednesday afternoon, there were enough parts ready to begin machine assembly. Although the team had an initial design, there was still a lot of interpretation and improvement required to get it running in the new environment. The goal was a machine that didn't need ongoing attention.

Ultimately, Esys brought the refining knowledge that helped create a fully functioning mask-making machine in record time. In an excellent example of manufacturing resilience across the three companies, much of the core manufacturing know-how was able to be adapted to meet this crucial need.

By three o’clock Friday afternoon, the first masks were being produced. When the call went out for employees to volunteer to transition from making automobiles to making masks and help distribute them across the community, GM filled up 13 shifts (315 people) in less than two hours.

“I sent out one email to the entire Southeast Michigan group of GM employees and everybody responded,” says Sean O’Sullivan, employee volunteer engagement officer, GM Corporate Giving. “A lot of our employees were looking to respond to COVID-19 in a positive way.”

GM has since added a second mask machine as well as 36 tables for manually welding masks to ear straps. There are now 5,000 GM employees who will produce masks through June. The lines can produce up to 100,000 masks per day.

The joint effort has also expanded to include three National Hockey League teams (the Red Wings, Blackhawks, and Flyers), who have donated the use of their Sani Sport machines for sanitizing the masks before they are shipped. Hundreds of employee volunteers are ensuring masks get to their destinations.

While GM estimates its mask production is achieving operational efficiency of 50-60%, because of the need to frequently change material, the project was never based on ROI. The company’s goal was to get as many masks out to first responders as quickly as possible. All the masks are donated.

Hitachi and GM share a common vision ― to power good in the world. Repurposing a GM facility from making transmissions to making masks is a manifestation of that vision. Innovation is more than creating a device or a product. For Hitachi, innovation is intricately tied to how it impacts the community and the world. This principle is woven into Hitachi’s culture. For Hitachi and GM, this joint endeavor was not about dollars and cents. It was about powering good, now and into the future. “When the opportunity arose to work with GM to use technology and innovation in the most fundamental helping way, it was an easy decision to invest not only dollars put people, resources and bandwidth,” said Jones. “This is just the tip of the iceberg as far as the kinds of things we can bring to our communities and customers.” Learn more about how Hitachi is powering good.

Release Date: June 2020

Solutions By: JR Automation, A Hitachi Group Company