Research on leaving valuable data to future generations is underway throughout the world. Current data storage media forms have a relatively short life expectancy and would not survive through fire or other disasters, making it ineligible for nearly permanent archiving applications. Hitachi took notice and is carrying out research & development into archive technologies that will enable the nearly permanent storage of data, focusing efforts on fused silica.

Video: Hitachi's fused silica recording technology

With the progress of information technology in our increasingly networked society, the recording media in use has moved quickly from paper to floppy disks, optical disks, hard drives, and a variety of other digital media. Demand is increasing for a long-term and reliable means of preserving valuable data, such as cultural heritage of historical significance and public documents, as well as personal records for future generations. Although optical disks and hard drives have sufficient recording density, for purposes of nearly permanent preservation, they are lacking in the durability needed to resist external stress and for long-term preservation capacity.

The goal of nearly permanent life is a given. The primary goals, however, are (1) the ability to withstand fluctuations in temperature and humidity as well as floods, fire, and other external stresses, and (2) for the archives not to need a specific device for the reading of their contents.

Hitachi finds that fused silica is a very promising material for recording media because it is chemically stable and highly resistant to heat and water, as well as being resistant to radiation.

In 2008, Hitachi launched a research project to develop nearly permanent data storage as part of its "Innovation Research," and in 2009, research results suggested that data recorded in fused silica could last for 300 million years.

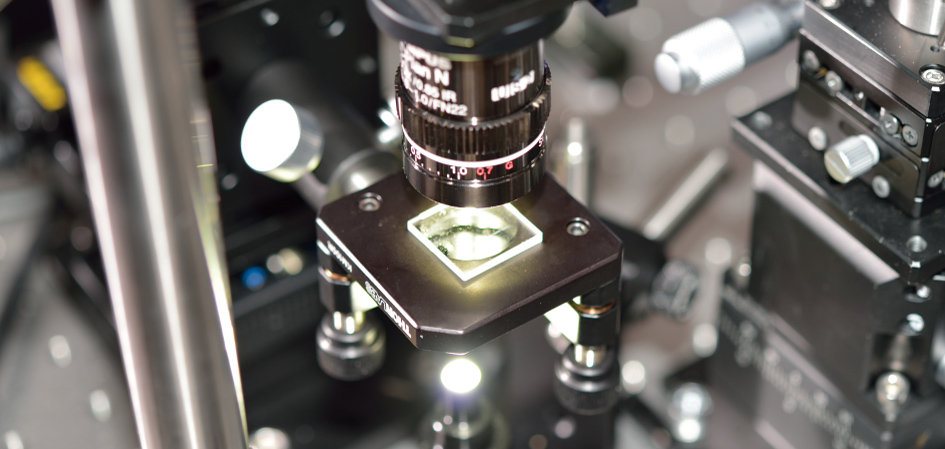

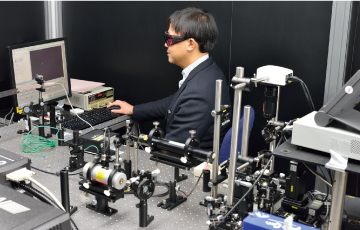

In 2011, Hitachi launched a joint research project with Prof. Kiyotaka Miura and Yasuhiko Shimotsuma, Ph.D. from the Kyoto University School of Engineering to improve recording density and simplify the reading process for data storage in fused silica. The result of this project was the use of a femtosecond pulse laser* for recording data and an optical microscope for reading data. The femtosecond pulse laser employs a laser pulse of less than one ten-trillionth of a second to form dots with a different refractive index inside the fused silica. Dots recorded like this represent ones, and the areas without dots represent zeroes, in this way recording digital data in multiple layers. To read the data, an optical microscope scans layer by layer to read the configuration of recorded dots.

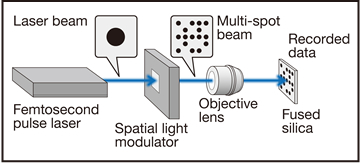

Graphic 1: A femtosecond pulse laser and spatial light modulator are used for high-density, multi-bit recording

The laser creates dots to record data

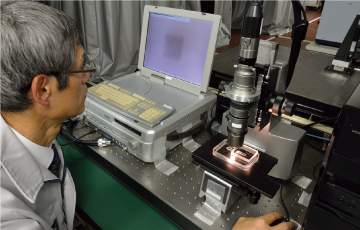

An optical microscope is used to read the data, and a computer processes the image

In 2012, the joint research project achieved a recording density comparable to a CD by recording four layers of data in fused silica. In 2013, the joint research project developed the technology to reach a recording density comparable to a DVD by recording 26 layers of data.

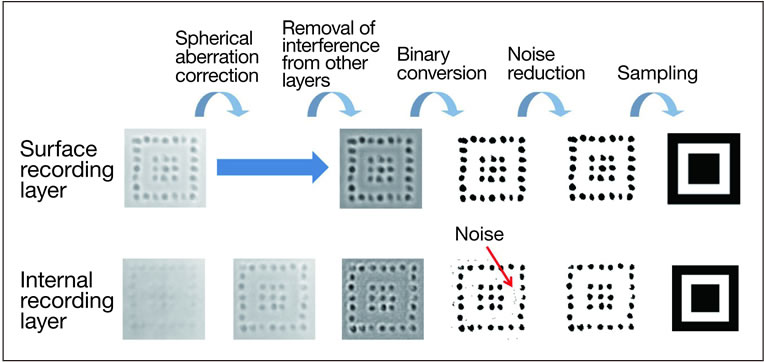

Dramatic innovations were needed in recording and reading data to achieve this level of density. The joint research project developed multi-layer recording technology and simultaneous multi-bit recording technology, using a spatial light modulator to enable high-speed and high-density recording. This makes it possible to simultaneously record around 300 bits of information. To improve recording density, the joint research project developed and used outline enhancing signal processing technology to reduce noise and artifacts from other layers.

Further, the joint research project proved that data recorded in fused silica was able to withstand accelerated temperature tests at 1,000°C for two hours and could have a nearly permanent life.

However, as the joint research project worked on increasing the number of layers to record to improve recording density, some unexpected issues arose. Recording more layers requires writing data deeper inside the fused silica, in layers that are only 60 micrometers apart. As data was recorded deeper inside the fused silica, the dots became distorted depth-wise, creating interference that caused errors in reading data from other layers. Another issue was that the dots recorded in deeper layers became less sharp when being read. These issues were due to spherical aberration caused by the difference between the refractive index of the air and that of the fused silica. The joint research project resolved these problems by using a spherical aberration correction lens, preventing the phenomena of elongation and blurring of the dots. To reduce reading errors and to meet reliability standards needed for practical application, the joint research project also developed and applied a new noise reduction algorithm. (See graphic 2)

The joint research project resolved the problems with multi-layer recording and succeeded in producing a prototype for 100-layer data storage in fused silica in 2014. This means that the joint research project proved that a nearly permanent life of 300 million years could be achieved for data storage at 1.5 GB/inch², which is comparable to Blu-ray discs™.

Possibilities still remain for further increasing of the number of layers.

Graphic 2: The data reading process met standards for practical application through using a spherical aberration correction lens and other innovative methods

Images in fused silica glass and a message for 300 million years in the future were sent into space aboard the Shin-en 2 probe

Currently, there are research initiatives underway around the world to develop long-life data storage using various methods, including semiconductor memory and the DNA of bacteria. However, none of these efforts have even come close to the technology developed by Hitachi in being able to store data for 300 million years or withstand temperatures of 1,000°C. Fused silica storage also has the added advantage that users can draw images, such as letters, artwork and photographs, by using dots in addition to storing digital data. In December 2014, a fused silica glass lithograph featuring images and a message for 300 million years in the future was created using this technology. These were launched into space on the Hayabusa 2 rocket as part of the payload for Shin-en 2, a small-sized space probe that was jointly developed by the Kyushu Institute of Technology and Kagoshima University.

Hitachi considers that cultural heritage such as written language, paintings, photographs, and sound recordings are valuable assets that should be preserved for future generations. Hitachi continues to work on research and development to preserve such valuable data for close to eternity using materials that are highly resistant to heat and water, as well as being resistant to radiation.

Release Date: March 2015

Solutions By: Research & Development Group, Hitachi, Ltd.