In a world that is increasingly aware of the implications from global warming, conversations around sustainability are taking a central role with corporate governance.

In Italy, action against climate change is becoming increasingly enshrined in policy. Alongside its UN partners, Italy has adopted the 2030 Agenda for Sustainable Development which provides a blueprint to achieve a better and more sustainable future for all. The Social Development Goals (SDGs) are key indicators that drive towards a more prosperous and sustainable future.

In the small town of Cotignola, 50km east of the historical city of Bologna, a manufacturer of cleaning and body care products is finding innovative solutions to combat the effects of climate change while also having a positive effect on their bottom line.

Founded in 1977, Madel is a leading Italian manufacturer of household brands of cleaning products. Their manufacturing process used vast quantities of water, which was used once and had to be treated at significant expense before being returned to the water network. Madel also suffered high electricity consumption due to excessive use of water pumps.

By partnering with Hitachi, Madel tackled these issues head-on and is now leading the industry through innovate technological solutions that challenge the sector to become more sustainable.

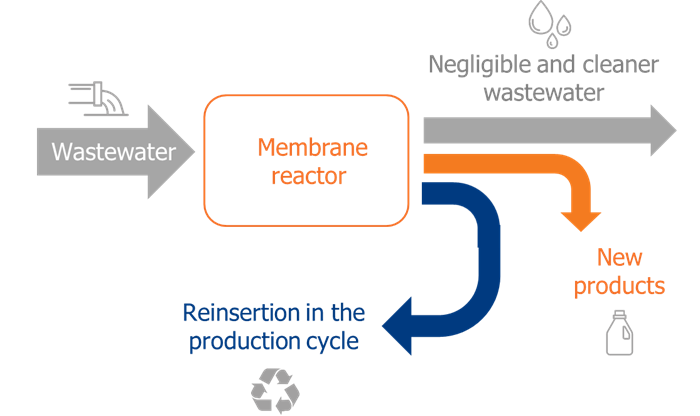

Hitachi conceived and implemented a multi-faceted solution that combines the physical and the digital. A Membrane Reactor* cleans the wastewater and removes the surfactant by products.

This allows Madel to do three things:

• Wastewater can be reused for production, reducing costs and the strain on resources;

• Wastewater returned to the network requires less treatment;

• The surfactant by-products can be retained and used to create new products.