Global water shortages continue to grow more dire as a result of population increases, urbanization, and rising standards of living. Remarkably, this issue could be solved through the use of low-cost desalination systems capable of turning the world's seawater into fresh water.

Urbanization and growing populations have generated constantly growing demand for water and water shortages in many areas around the globe. Countries in the Middle East, Africa, and Asia, as well as certain parts of North America, have experienced severe water shortages. Despite high expectations for desalination systems as a solution for removing salt from seawater to render drinking water or to meet industrial water needs, due to the high cost of desalination, such systems have yet to enter widespread deployment.

Demonstration facility, Water Plaza Kitakyushu

In 2008, seeking to apply advanced Japanese water infrastructure technologies to tackle this global issue as partners, a number of Japanese companies established the Global Water Recycling and Reuse System Association, Japan (GWRA). In 2009, Hitachi and Toray Industries, Inc., core members of the association, took the initiative in proposing a new seawater desalination system to the New Energy and Industrial Technology Development Organization (NEDO), a national Japanese research institute. This system features both low energy consumption and low environmental impact. The proposed system was subsequently adopted as a NEDO demonstration project. To move forward, Hitachi and Toray Industries, Inc., created the Global Water Recycling and Reuse Solution Technology Research Association (GWSTA) in 2010. In the same year, in cooperation with the City of Kitakyushu, GWSTA began building Water Plaza Kitakyushu, among Japan's largest water desalination plants based on energy-saving technologies.

Thus, Water Plaza Kitakyushu opened in December 2010 as a demonstration facility for energy-saving seawater desalination and for tests of various water treatment devices in a real-world environment. This plant incorporates a unique system proposed by Hitachi et al., which integrates the seawater desalination process and a sewage water reuse process.

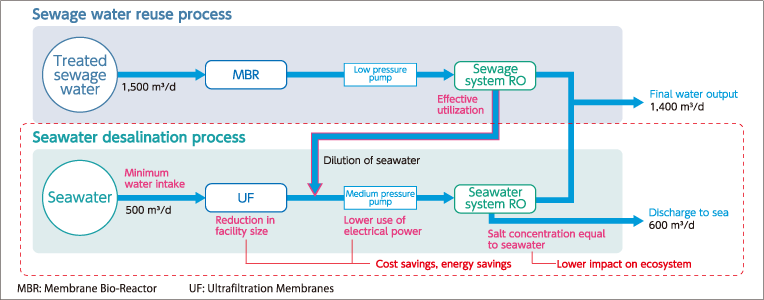

Benefits of the “RemixWater” system include use of water reclaimed from wastewater reuse process to dilute and reduce the salt concentrations of seawater. To remove salt from seawater and make fresh water, conventional desalination systems pump seawater under pressure and filter it through membranes with microscopic holes in a process called reverse osmosis (RO). “RemixWater” is an integrated system that uses water reclaimed from wastewater reuse process to dilute seawater before subjecting it to RO. Higher concentrations of salt require higher pressure to pass through the membranes and remove salt, which results in higher pumping costs. Since pumping costs account for about half of operating costs, “RemixWater” can significantly reduce the cost of desalination compared to conventional seawater desalination plants.

Overview of the “RemixWater” System: An integrated system for seawater desalination and sewage water reuse

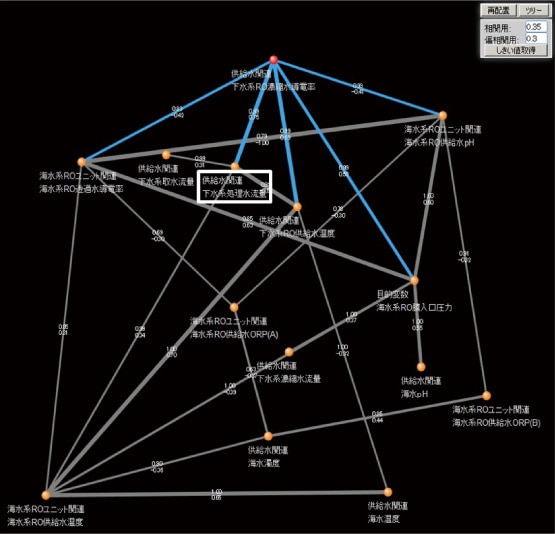

Analysis using AI technology to find a solution to reduce clogging of RO membranes

It took Hitachi's unique combination of expertise and knowhow to develop this system, which is based on the simple idea of using treated water to dilute the salt concentrations of seawater. One example involves incidents in which particulates in the treated sewage water clogged the RO membranes. The response implemented involved adjustments in the amounts of chemicals used to treat the sewage water. Drawing on knowledge accumulated over three years of operation, the demonstration project has achieved over 30% reductions in energy consumption compared to conventional seawater desalination plants.

In addition, the key technology in seawater desalination systems, including “RemixWater,” is RO, which filters seawater into fresh water. But continuous filtration over long periods tends to clog the membranes, gradually degrading membrane performance and driving up pumping costs. Preventing this clogging can yield energy and cost savings.

At the same time, controlling operations to reduce clogging is extremely difficult, because the causes of the clogging are still not completely understood. Preventing clogs more effectively remains a matter of ongoing trial and error.

To devise better methods to prevent clogging, Hitachi applied its proprietary AI technology to analyze operational data at Water Plaza Kitakyushu and identified factors that correlate with clogging. Based on these findings, Hitachi also calculated the efficacy of operational control methods to reduce clogging and determined that about 6% reductions in pumping costs could be achieved.

Sewage water treatment plant in the eThekwini Municipality, where a demonstration project has begun producing water to meet drinking water standards

Water Plaza Kitakyushu has attracted about 7,500 visitors, including nearly 1,900 visitors from overseas (as of November 2016). Officials from the eThekwini Municipality, known as the City of Durban, the Republic of South Africa, also visited and expressed interest in “RemixWater,” which led to Hitachi's participation in a new project under the framework of the International Energy Consumption Efficiency Technology and System Demonstration Project initiated by NEDO.

The average annual rainfall in the Republic of South Africa is about half the world average. With the country's third largest population, the eThekwini Municipality has struggled to meet water demand that exceeds available supply. While the city had considered building a seawater desalination plant, the high operating costs posed a major obstacle. Due to the system's lower operating costs, officials have realized the city could use the energy-saving “RemixWater” system.

A demonstration project in the eThekwini Municipality began in 2016. While the goal of the demonstration in Water Plaza Kitakyushu was to produce water for industrial use, the new goal at this stage is the stable production of water that meets the drinking water standards of the Republic of South Africa. Based on the results of this new demonstration project, Hitachi is planning to accelerate its efforts to commercialize “RemixWater” and to maintain its focus on the challenge of solving global water shortages.

Release Date: March 2017

Solutions By: Hitachi, Ltd. Water Business Unit