Deepwater production activities for oil and natural gas have accelerated in response to the growing demand for energy. In recent years, floating production facilities, known as "FPSO" (Floating Production, Storage, and Offloading), have been playing a central role in resource development. Hitachi's centrifugal compressors for FPSO systems are a key component in this process and are making a difference on the seas in Brazil's offshore production of seabed resources.

Video:The Power of Gases that Supports the World

As worldwide demand for energy increases, center stage in the development of oil and gas fields has been moving from land to offshore, to areas like the Gulf of Mexico and the North Sea. FPSO systems have become a major means for extracting resources from beneath the sea, replacing fixed platform systems. FPSO systems can shorten in-ocean construction time and can be used regardless of seabed depth. With an FPSO system, oil and gas extracted from the ocean depths can be stored in onboard tanks and then offloaded directly to tankers later. FPSO systems need powerful compressors to extract crude oil and gas efficiently. By using compressors to assist in the process, oil and gas recovery can reach 40 to 50%, effectively doubling the recovery rate of conventional methods.

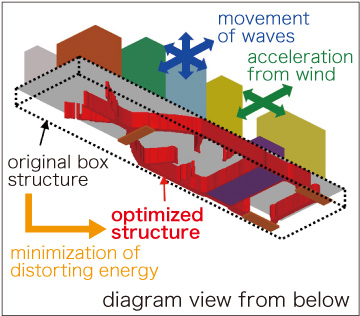

The baseplate was designed to ensure strength and reliability while weighing 23% less than the conventional design.

Hitachi developed Japan's first compressor in 1911. Since then, Hitachi has developed compressors that have been used in a wide range of industries, including electric, electronics, automotive, steel, chemical, medical, and food. Several years ago, Hitachi started working intensively on the development of centrifugal compressors for FPSO systems.

Compressors are specialized products that are designed and manufactured individually to meet each customer's precise specifications. For Hitachi, making progress in research and development of more efficient compressors for FPSO systems is a high priority and is being treated as an especially important project in the satisfying of customer needs. FPSO facilities can be described as modified tankers. Compressors for FPSO systems have to achieve high reliability and need to be able to withstand the vertical movements and twisting forces caused by the ocean's waves and wind. At the same time, the weight of the system needs to be kept to a minimum. After extensive research and development, Hitachi conducted analysis to check system strength and resistance to trembling and jolting forces. This led to a design method using a baseplate reinforced with a girder structure made from lighter materials that is strong enough to operate in an ocean environment. This design method appealed to customers, and Hitachi received its first order for centrifugal compressors for an FPSO system in 2011.

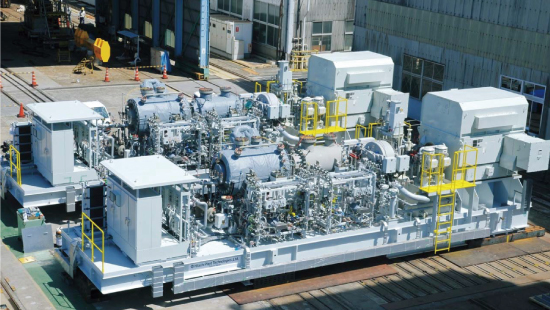

Compressor train assembled in Hitachi's Kasado Works will be transported to Thailand to be incorporated into the compressor module. It will then be installed on a ship in a Singapore shipyard.

Hitachi centrifugal compressor in operation on a ship

To become more energy independent, Brazil is accelerating its development of offshore resources. The compressors that Hitachi delivered for production activities in Brazil's offshore fields are being operated by OSX3 Leasing B.V. Corporation. The time between the system being ordered and its delivery was only 11 months. This was a challenging project for Hitachi since it required close coordination of simultaneous work in R&D and construction. Based on the optimized design, Hitachi reinforced the strength of the baseplate and supported the structure in three places using specialized parts so that the distortions caused by the ocean's waves and wind would not affect the compressor on the deck. This method also kept the system compact and lightweight. Hitachi applied its unique technology for structural optimization, strengthening the placement of the reinforcing girders and minimizing weight.

Centrifugal compressors are usually provided as a package, meaning that a drive, such as a motor, steam turbine, or gas turbine, and a transmission are mounted on the same baseplate as the compressor. Even though these systems were structurally optimized to be as light as possible, the compressors ordered were huge (17 meters long, 4 meters wide, and weighing 150 tons). Due to the scale of the project, the baseplate construction, assembly, and pipefitting were done at Hitachi's Kasado Works, a plant that is also used to manufacture railway trains.

This is an example in which close cooperation between various divisions within the Hitachi Group made it possible to deliver centrifugal compressors for a FPSO system on time in August 2012. Since then, the four compressors that were ordered have been working without any problems. Customers value Hitachi's ability to successfully deliver this kind of complex rush order. The capacity to develop unique solutions that address individual business challenges as well as proven expertise in engineering and technology are key strengths for Hitachi.

In 2012, Hitachi received six additional orders for centrifugal compressors for FPSO systems to be used off the coast of Brazil, and six more orders were received in 2015. Hitachi also established HITACHI-MYCOM Maintenance & Solutions Ltd. in Sao Paulo, Brazil as a base for maintenance and related services in 2012. There are major oil and gas reserves off the coast of Brazil, and the demand for FPSO systems is expected to grow. Today, Hitachi continues to focus on Brazil while also aiming to expand to markets in Africa and Asia.

HITACHI-MYCOM was established in Sao Paulo, Brazil as a base for maintenance services.

Furthermore, Hitachi has been making tremendous progress in the development of Super High-Pressure Compressors. These are expected to be used for Enhanced Oil Recovery (EOR) for FPSO systems as well as CCS (Carbon Dioxide Capture and Storage) in deep water. However, these compressors have to meet strict requirements for super high-pressure discharge. In addition, they need to have highly reliable structures and be resistant to trembling and the corrosive effect of strong acids produced by various gases. Hitachi is aiming to advance the technology to meet those requirements through prototype development and testing.

Oil and natural gas have become more and more important energy resources for emerging countries as well as for the rest of the world. Hitachi strives to support people's lives worldwide by developing and manufacturing compressors that are essential for efficient and stable oil and gas production.

Release Date: July 2015

Solutions By: Industrial Products Business Unit, Hitachi, Ltd.