Water is essential to support human life. To help countries and regions suffering from shortages of water, planning is underway for large-scale projects that will send water from regions with abundant water resources so as to provide stable water supply. Such projects require highly efficient pumps—the heart of any water supply system.

For more than 100 years, Hitachi has been advancing its manufacturing technology for pump

While some countries and regions have abundant water resources, other places often experience critical shortages. This affects people's daily lives and limits agricultural yields development. To address the world's uneven distribution of water resources, demand for pumps that can transfer water over long distances has become stronger.

Hitachi's history in pump manufacturing dates back more than a century. Hitachi has been developing a wide range of pump and water treatment technologies for securing water resources, for drinking water and sewage treatment, and for recycling and reusing water. In 1950, Hitachi was commissioned by Tohoku Electric Power to supply one of Japan's largest lift pumping plants for the Numazawanuma Pumped Storage Power Station. In 1958, Hitachi received an order for adjustable vane impeller pumps for what was then East Pakistan (currently Bangladesh). Since then, Hitachi has continued to refine its technologies, delivering pumps for large-scale projects overseas.

Toshka Pumping Station was built along the side of Lake Nasser

Hitachi's large-scale, Vertical Centrifugal Turbine Pump

Entering the 21st century, Hitachi accelerated its participation in overseas projects. In Egypt, Hitachi played an important role in the Toshka Project to green the desert and build a new city by bringing water from Lake Nasser. Hitachi took its technological leadership in the project, which was executed by a multinational consortium. Hitachi's international contribution was greatly appreciated by Arab Republic of Egypt.

In China, Hitachi participated in the South to North Water Transfer Project by completing the construction of the Bao Ying Pump Station, which is involved in taking water from the south (Yangtze River basin) to supply large areas in the north (Tianjin River basin), thereby resolving serious water shortages. In this way, Hitachi has built a record of global accomplishment.

In 2004, Hitachi was commissioned to renovate the Edmonston Pumping Plant, one of the world's largest lift pumping plants. The pumping plant is the most important piece of water supply infrastructure in the 960km-long waterway connecting Northern and Southern California. It is an indispensable facility for supplying water from Northern California to urban areas, such as Los Angeles and San Diego, and agricultural areas in Southern California. This requires pumping water up 1,926 feet (or about 600 meters), which introduced another challenge-that of how to reduce the power consumption of the 80,000 horsepower (60,000 kW) synchronous motor used to drive the massive pumps. Utilizing its extensive expertise in all aspects of pump technology, Hitachi succeeded in developing highly efficient massive turbine pumps. This earned Hitachi high marks from the State of California's Department of Water Resources.

Vertical Multi Stage Centrifugal Turbine Pumps achieved the world's highest level of pumping efficiency while contributing to reductions in CO2 emissions.

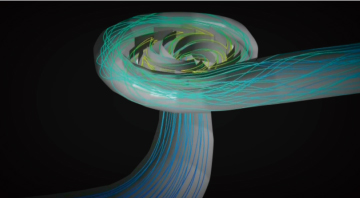

"CFD", highly advanced analysis technology, is used to create highly efficient pumps

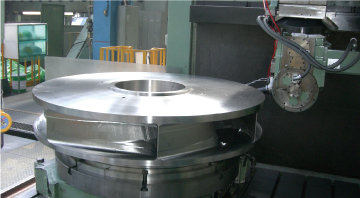

Machining impellers using computer numerical control for precision

The Edmonston Pumping Plant is the result of Hitachi's advanced pump technologies, integrating the strengths of the entire Hitachi Group from development and design to manufacturing. At the foundation of this work, highly advanced analysis technology called Computational Fluid Dynamics (CFD) was used to accurately simulate the flow of water in the pump. CFD uses computers to calculate water flow. This, coupled with the design optimization technology and knowhow accumulated by Hitachi, makes it possible to create pump configurations that ensure high reliability and excellent performance.

Utilizing the strength of these design technologies, Hitachi was able to succeed in design optimization to increase pumping efficiency and reliability. Hitachi also manufactured major parts such as impellers and guide vanes utilizing precision technology and the latest computer numerical control machining* to achieve pumping efficiency at the world's highest level. These improvements in pump efficiency had a significant effect on saving energy and helped to reduce CO2 emissions.

Until water resources are stabilized and secured, food crises might occur. Issues surrounding water resources are serious and urgent for countries around the world. In response to these circumstances, Hitachi has been developing its global pump business by advancing massive projects in the world. Building on achievements from over 100 years of working on pump technologies for irrigation, drinking water, sewage and wastewater treatment, industrial plant, and power generation, Hitachi continues its efforts to resolve problems surrounding the world's water resources.

Video:Stories of Technology "Pump"

Release Date: November 2014

Solutions By: Industrial Products Business Unit, Hitachi, Ltd.