Globalization has transformed the linear and local supply chains into highly complex and global supply networks. The disruption of these global networks and the strain on manufacturing sector imposed by the COVID-19 global pandemic have trembled the manufacturers and retailers to rethink about their supply chain networks and reimagine it for tomorrow’s needs.

Impact from COVID-19 situation is not limited to a short term financial aspect but due to multi-phases lockdown and less than a smooth inter-state labor migration process leading to social distress, a halt has been witnessed affecting the Indian Economy and other big economies in the world which may further widen and may impose a higher & long term risk unless managed effectively and swiftly.

Advancements in Industry 4.0 technologies such as the internet of things (IoT), artificial intelligence (AI), machine learning, blockchain, and big data analytics are paving the way for agile, transparent and stronger networks capable of weathering supply and demand shocks. Digital Supply Chain, therefore, becomes a fundamental and not just a convenience in the post COVID-19 world. Hitachi is leading this digital-led transformation and evolution of Industry 4.0 and Society 5.0 with its globally recognized OT x IT expertise and Social Innovation Business.

Hitachi strongly feels the critical need for digital intervention in the following areas within supply chain.

The global pandemic has exposed the fragility of traditional supply chain as governments, suppliers, retailers, and customers struggle to procure essential products and materials. Digitization of supply chain creates a window of opportunity for retailers and manufacturers to recuperate faster and build a customer-centric network.

To aid manufacturers and retailers recover from the global pandemic crisis and transform their network for optimal results, Hitachi Vantara, a Hitachi Group Company, is leveraging its cutting-edge Lumada applications, edge intelligence and co-creation services to usher in Social Innovation Business.

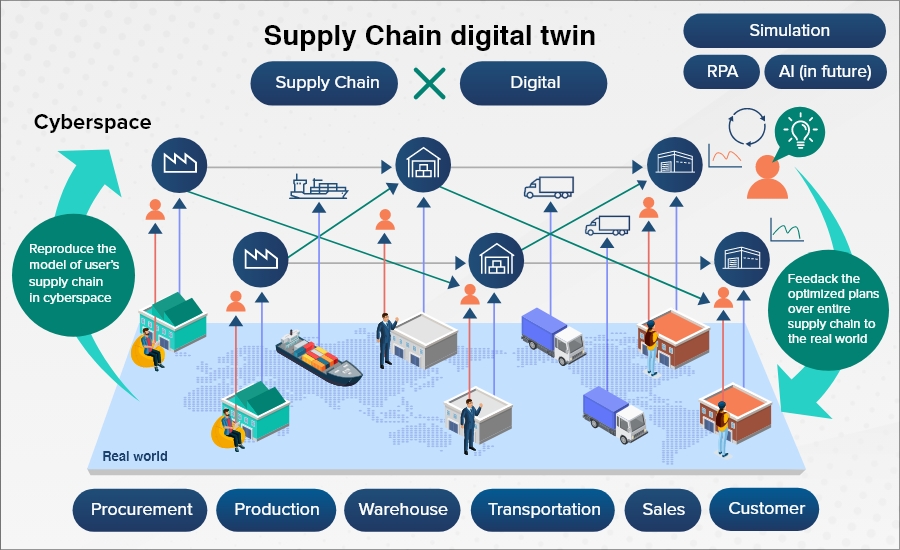

Driven by the need to mitigate supply risks in the current scenario, Hitachi has developed its Supply Chain Optimizer solution, which sets forth benchmarks in sourcing rules, stocking points, delivery route, and re-balancing inventory at optimized cost.

An IoT enabled Supply Chain Command Center has made possible end-to-end supply chain visibility from remote. Linked with simulations, the solution helps retailers monitor change in demand, production rate, transportation route, supplier risk, and change in inventory level, thereby empowering businesses to optimize customer response.

At the global level, Hitachi is enabling the seamless adoption of AI-powered tools. Through collaborative creation, Hitachi has helped Seiyu GK ("Seiyu"), a subsidiary of Walmart, adopt the Hitachi Digital Solution for Retail in stores all over Japan to help curb stockout, food waste and losses. An AI-enabled Automatic Planning System has been introduced for Nichirei Foods, a pioneer in frozen food, for optimized production and manpower allocation planning.

Additionally, Hitachi has collaborated with Microsoft Corp. to accelerate the digital transformation of the manufacturing and logistics industries across Southeast Asia, North America and Japan. This alliance will support in meeting the growing demand for predictive maintenance and process automation in remote areas and support enterprises as they tackle the challenges infused by the COVID-19 pandemic.

When we look at solutions in India, Tata Hitachi Construction Machinery Company Pvt. Ltd., a Hitachi Group Company, has developed BOTS (a software application) to help manufacturers manage volume and compliance and apply predictive analysis on machine performance.

Reproduces the supply chain in Cyber Space, and achieves overall optimization for daily changes that are difficult to follow in the real world. You will foresee the future.

Hitachi is committed to marshalling solutions that improve the Quality of Life of people and enhance the social, environmental and economic values of the nation. Hitachi has put its Social Innovation Business solutions into action during the COVID-19 induced lockdown in India. Hitachi Payment Services, a Hitachi Group Company, deployed Hitachi Money Spot Mobile ATMs across multiple places in and around Ahmedabad to empower people in rural & semi-urban areas to meet their cash shortage needs without traveling long distances.

The current digital and disruptive environment demand agile and resilient networks. The longer businesses wait to embrace digital transformation, the more likely the competition will leapfrog over them. Supply Chain 4.0 assures supply chain excellence and adaptability to disruptive forces.

Hitachi is helping businesses ride the digital wave and embrace Industry 4.0 solutions for a robust, customer-first supply chain network.

1 - https://www.financialexpress.com/industry/sme/msme-fin-47-startups-smes-likely-to-shutdown-scale-down-in-six-months-due-to-covid-lockdown-according-to-localcircles-survey/1941333/

2 - https://www.mondaq.com/india/operational-impacts-and-strategy/936014/coronavirus-covid-19-and-indian-economy

3 - https://www.entrepreneur.com/article/349229

4 - https://www.supplychaindive.com/news/retailers-struggle-inventory-forecasting/552164/

5 - https://www.bcg.com/en-in/capabilities/operations/digital-supply-chain.aspx

6 - https://www.bcg.com/en-in/capabilities/operations/conquering-complexity-supply-chains-digital-twins.aspx